Máquina de moagem de farinha de amendoim | Moedor de farinha de nozes

| Poder | 3 KW |

| Capacidade | 200-600 kg/h |

| Dimensões | 1200 x 1050 x 1400 (1700) mm |

| Ajustável em Granulometria | Malha 10-80 (pó), 3-6 mm (granulados) |

| Tensão | 380 V |

| Frequência | 50 Hz |

| Materiais aplicáveis | Amendoim, sésamo, amêndoa, noz, soja, café, cacau |

Agora você pode pedir detalhes técnicos aos nossos gerentes de projeto

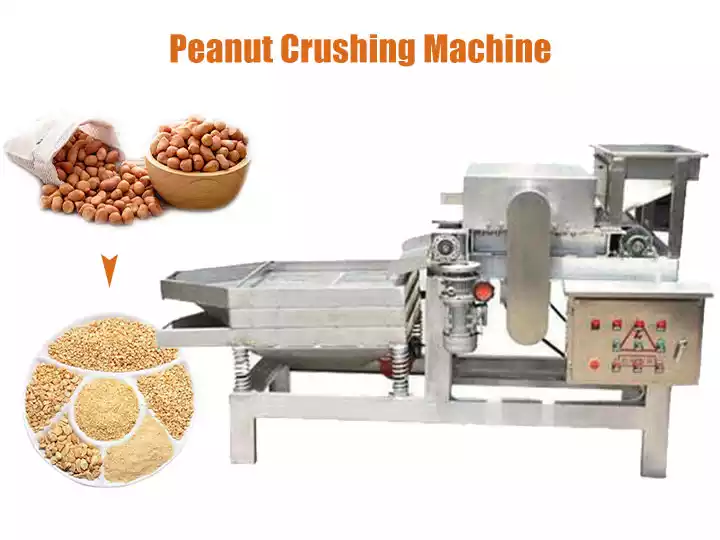

A máquina de moagem de farinha de amendoim é um dispositivo de alta eficiência especialmente projetado para moer e processar amendoim e outras sementes oleaginosas. Esta máquina é fácil de operar e realiza o processo de trituração em uma única passagem sem produzir resíduos oleosos. Com capacidade de produção de 200-600kg/h, é adequada para produção comercial e industrial.

O equipamento apresenta resistência à corrosão e durabilidade, garantindo higiene e segurança. Pode acomodar várias matérias-primas, incluindo amendoim, sementes de sésamo, amêndoas, nozes, grãos de café e cacau. Através de um design de corte em múltiplas etapas e moagem por rolos, pode processar materiais em pó fino ou partículas grossas, atendendo a diversas necessidades de produção.

Especificações do moedor de farinha de amendoim

| Parâmetro | Moinho de Amendoim |

| Poder | 3 KW |

| Capacidade | 200-600 kg/h |

| Dimensões | 1200 x 1050 x 1400 (1700) mm |

| Tensão | 380 V |

| Frequência | 50 Hz |

| Material | Aço inoxidável 304 |

| Ajustável em Granulometria | Malha 10-80 (pó), 3-6 mm (granulados) |

| Materiais aplicáveis | Amendoim, sésamo, amêndoa, noz, soja, café, cacau |

Aplicações da máquina de moagem de farinha de amendoim

O moinho de farinha de amendoim é adequado para moer várias sementes oleaginosas e grãos, podendo ser usado para:

- Moer amendoim, sementes de sésamo, amêndoas, nozes, soja e outras oleaginosas e culturas oleaginosas em pó ou granulado.

- Produz farinha de amendoim, farinha de sésamo, farinha de nozes e outros ingredientes para a indústria alimentar.

- Processamento contínuo em fábricas comerciais e de pequena escala.

- Cenários de processamento de alimentos de alto rendimento e grande volume para evitar oxidação por armazenamento prolongado.

Esta máquina de moagem de farinha de amendoim oferece alta versatilidade e flexibilidade para uso generalizado nas indústrias de alimentos, panificação, temperos e snacks.

Princípio de funcionamento do moinho de farinha de sementes e nozes

A máquina de moagem de farinha de amendoim consiste em um cortador secundário de engrenagem e um rolo de moagem primário:

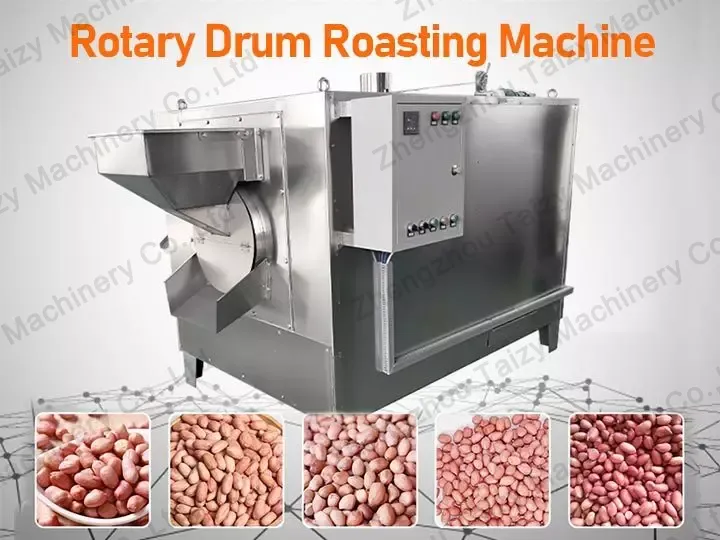

- As matérias-primas passam primeiro por descascamento e torrefação antes de entrarem no corpo da máquina.

- A fatiagem preliminar é realizada pela rotação de alta velocidade do cortador de engrenagem.

- O rolo de moagem então realiza o processamento de pó fino por compressão por rolagem.

- A folga entre o rolo de moagem e o cortador de engrenagem é ajustável para alcançar diferentes tamanhos de partículas: de granulado grosso (3-6mm) a pó fino (malha 40-60).

- Usar apenas o cortador de engrenagem sem o rolo de moagem produz produtos granulares.

Toda a máquina funciona suavemente com baixo ruído. O processamento não gera oleosidade e evita que o material cru grude na máquina.

Nota: Se necessário, também oferecemos máquinas de descascamento de casca de amendoim e moinhos multifuncionais de torrefação de nozes.

Destaques da máquina de moagem de farinha de nozes

- Alta produção: capacidade de processamento de 200-600kg por hora atende às demandas de produção em grande escala.

- Funcionalidade versátil: capaz de produzir tanto farinha de amendoim quanto granulado para atender a diversas necessidades de processamento.

- Operação simples: fácil de instalar, operar e manter, requer apenas um operador.

- Higiénico e durável: toda a unidade construída em aço inoxidável resistente à corrosão 304 para fácil limpeza.

- Granulometria ajustável: livremente ajustável de granulado grosso a pó fino para atender a diversas aplicações.

- Baixa oleosidade, sem entupimentos: sem vazamento de óleo ou aderência na máquina durante o processamento, ideal para produção contínua de alto volume.

Seja processando farinha de amendoim ou granulado, nosso equipamento lida com facilidade, ajudando seu negócio de processamento de alimentos a crescer de forma constante. Contacte-nos hoje para tornar sua produção mais eficiente, higiénica e estável!