Línea de producción de cacahuetes recubiertos de harina | Línea de procesamiento de recubrimiento de cacahuetes

| Tostadora de maní | 50-500 kg/h |

| Máquina peladora de cacahuetes | 200-1000 kg/h |

| Máquina de recubrimiento de maní | 30-300 kg/h |

| Máquina de freír | 500kg/hora |

| Horno oscilante | 80-300 kg/h |

| Máquina sazonadora | 300-1500 kg/h |

| maquina de enfriamiento | 80-100kg/hora |

| Máquina de envasado | 50-100 bolsas/min |

Ahora puede solicitar detalles técnicos a nuestros jefes de proyecto

La línea de producción de cacahuetes recubiertos está diseñada específicamente para el procesamiento a gran escala y totalmente automatizado de cacahuetes recubiertos y otros aperitivos de legumbres recubiertos. Utiliza cacahuetes, habas, anacardos, nueces de macadamia y otros ingredientes como materias primas principales, pasando por procesos como tostado, descascarillado, recubrimiento, horneado, sazonado, enfriamiento y envasado.

El producto final presenta un recubrimiento uniforme, una apariencia atractiva y una textura crujiente, lo que lo hace muy popular en el mercado. Es ideal para la inversión y el uso por parte de plantas de procesamiento de alimentos y empresas de aperitivos de tamaño mediano a grande.

Esta línea de producción de cacahuetes recubiertos cuenta con un alto grado de automatización, requiriendo típicamente solo 4 trabajadores para operar toda la línea. Esto no solo reduce eficazmente los costos de mano de obra y los gastos de producción, sino que también mejora significativamente la eficiencia de producción y la calidad del producto.

Aplicación de la línea de producción de recubrimiento de maní.

- Productos de cacahuete: cacahuetes azucarados, cacahuetes recubiertos de polvo, cacahuetes de miel, cacahuetes picantes, cacahuetes de mostaza, cacahuetes de chocolate, hamburguesas de cacahuete, etc.

- Productos de legumbres: habas recubiertas, judías verdes recubiertas, guisantes recubiertos, edamame recubierto, etc.

- Productos de frutos secos: anacardos recubiertos, nueces de macadamia, semillas de girasol, etc.

- Aperitivos diversificados: se puede ampliar para incluir patatas fritas crujientes picantes, alimentos inflados, caramelos de chocolate, aperitivos recubiertos de marisco y otros aperitivos especiales.

Ventajas de la línea de producción de cacahuetes recubiertos

- Los parámetros del proceso de toda la línea de producción de cacahuetes recubiertos (temperatura, velocidad, ángulo, etc.) se pueden ajustar libremente para lograr una producción continua con una mínima supervisión manual.

- El recubrimiento es uniforme y de grosor constante, lo que resulta en un acabado superficial liso y atractivo, una textura crujiente y altas tasas de recompra.

- Las capacidades de producción personalizadas se pueden adaptar para satisfacer las necesidades de operaciones de procesamiento tanto a pequeña como a gran escala.

- Todas las piezas en contacto con los alimentos están hechas de acero inoxidable de grado alimenticio, que es duradero, fácil de limpiar y cumple con las normas de seguridad alimentaria.

- Los parámetros ajustables incluyen el ángulo de inclinación, el método de calentamiento y la velocidad, con accesorios opcionales como sistemas de pulverización y sistemas de recolección de polvo.

- Adecuado no solo para cacahuetes, sino también para procesar diversas legumbres y frutos secos, satisfaciendo diversas demandas del mercado.

Equipo principal de la línea de producción de cacahuetes recubiertos

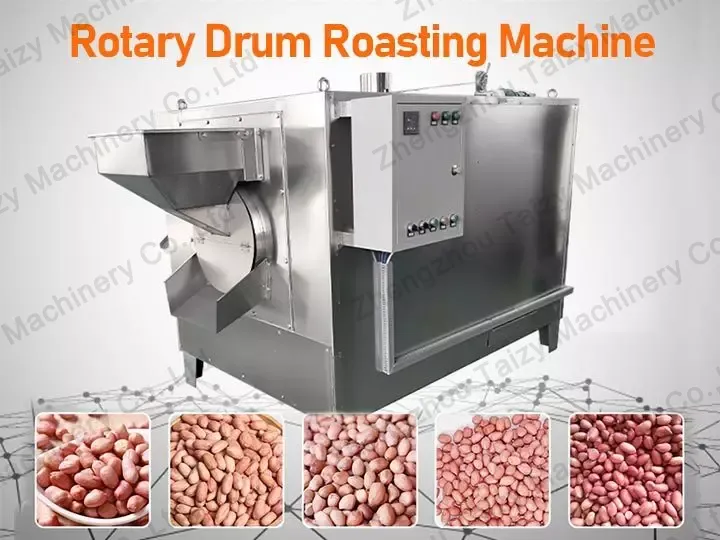

Tostadora de maní

El tostador de cacahuetes se utiliza para tostar los núcleos de cacahuete. El diseño del tambor puede hacer que los cacahuetes se calienten de manera uniforme y no se peguen fácilmente. Y puede reducir la tasa de rotura de los cacahuetes.

Al mismo tiempo, la humedad de los cacahuetes se reducirá a menos del 5%. Puede elegir entre varios métodos de calentamiento, como calefacción eléctrica, calefacción a gas y calefacción a carbón.

| Modelo | Dimensión (mm) | Capacidad (kg/h) | Potencia (kilovatios) | Electricidad Calefacción (kw) | Calefacción a gas (kg) |

| TZ-1 | 3000*1200*1700 | 80-120 | 1.1 | 18 | 2-3 |

| TZ-2 | 3000*2200*1700 | 180-250 | 2.2 | 35 | 4-6 |

| TZ-3 | 3000*3300*1700 | 280-350 | 3.3 | 45 | 6-8 |

| TZ-4 | 3000*4400*1700 | 380-450 | 4.4 | 60 | 8-10 |

| TZ-5 | 3000*5500*1700 | 500-650 | 5.5 | 75 | 10-12 |

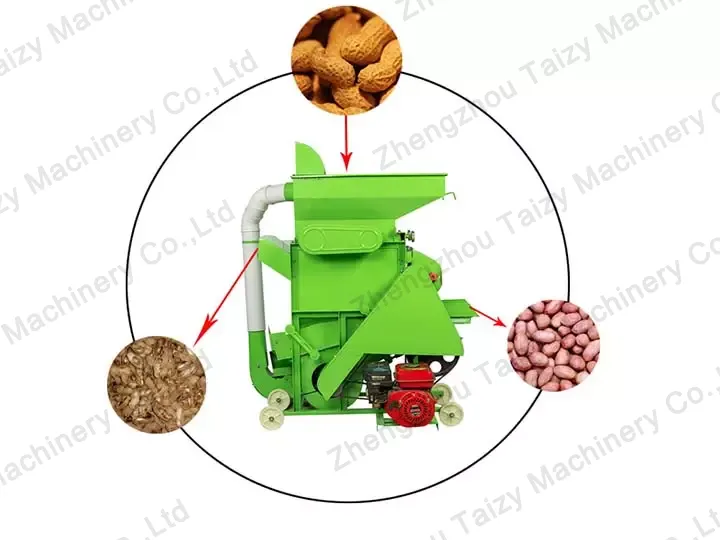

Peladora de maní

La máquina peladora de cacahuetes en seco puede separar la piel del cacahuete del núcleo de cacahuete. La tasa de pelado de la máquina es superior al 96%.

| Tarifa Completa | ≥96% |

| Dimensión | 1100*400*1000mm |

| Capacidad | 200-250 kg/hora |

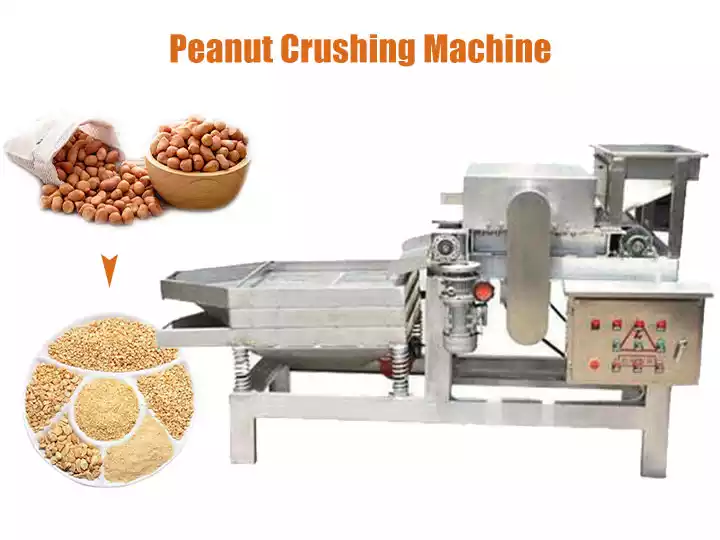

Máquina para hacer cacahuetes recubiertos

La máquina de recubrimiento de cacahuetes es la máquina principal en la línea de producción de cacahuetes recubiertos de harina. La máquina de recubrimiento sirve para hacer que el material ruede y se frote dentro de la máquina bajo la acción de la fuerza centrífuga.

Luego, el núcleo de cacahuete se mezcla uniformemente con azúcar en polvo y la superficie del cacahuete recubierto hecho por nuestra máquina es lisa.

| Fuerza | 1,1 kw/380v, 220v |

| Peso | 180kg |

| Dimensión | 1200*1000*1300 |

| Diámetro | 1000 mm |

Horno oscilante de maní

El tostador oscilante de cacahuetes es una máquina que tuesta los cacahuetes envueltos mediante calefacción eléctrica y calefacción a gas. Esta máquina es fácil de operar. Los trabajadores solo necesitan verter los cacahuetes en el tostador de cacahuetes. Luego, esperan 15 minutos para sacarlos del horno.

| Fuerza | 25,75 kw |

| Voltaje | 380v/50hz |

| Tamaño | 2200*2000*1500mm |

| Poder de calefacción | 25kw |

| Poder de giro | 0,75 kw |

| Peso | 500 kilos |

| Velocidad | 40-60 veces/minuto |

Máquina sazonadora de cacahuetes

La máquina sazonadora de maní puede mezclar bien los maní y los condimentos. Nuestra máquina se puede conectar con un dispositivo de pulverización externo o con un vertido manual de material. Los usuarios pueden agregar el condimento requerido a la máquina según sus necesidades.

| Fuerza | 1,1 kw/380v |

| Peso | 150 kilos |

| Dimensión | 1000*800*1300mm |

| Diámetro del barril | 1000 mm |

| Capacidad | 300kg/h |

Máquina de enfriamiento de maní

El enfriador de maní es una máquina que se utiliza para reducir la temperatura del maní envuelto. Esto es para preparar el embalaje posterior. La máquina consta principalmente de una parte de refrigeración y una parte de almacenamiento.

| Modelo | Capacidad (kg/h) | Potencia del ventilador (kw) | Voltaje/Frecuencia | Dimensión (mm) |

| TP-1 | 200-300 | 1.1 | 380V/220v 50HZ | 1300*600*600 |

Máquina envasadora de gránulos de maní

La máquina envasadora de gránulos de cacahuete es adecuada para envasar gránulos de cacahuete, palomitas de maíz, diversos frutos secos y otros materiales granulares. Es también la última máquina en la línea de producción de cacahuetes recubiertos.

| Estilo de bolso | Sello trasero (personalizable) |

| Velocidad de embalaje | 37-72 bolsas/min o 50-100 bolsas/min |

| longitud del saco | 30-180 mm |

| Rango de llenado | 22-220ml |

| El consumo de energía | 1,8 kw |

| Peso | 250 kilos |

| Dimensiones | 650*1050*1950mm |

| Tamaño del cartón | 1100*750*1820mm |

Resumen

La línea de producción de cacahuetes azucarados necesita ser personalizada según la producción específica del cliente y el tamaño de la planta de producción. Como proveedor de confianza de maquinaria de procesamiento de cacahuetes. Nuestra empresa ofrece una serie de servicios personalizados como un flujo de proceso perfecto y personalización de equipos.

Si está buscando equipos eficientes, seguros y personalizables para la línea de producción de cacahuetes recubiertos, no dude en contactarnos para obtener especificaciones detalladas y soluciones personalizadas.