Exportación de máquinas de línea de procesamiento de cacahuetes recubiertos a Nigeria

Great news! We have completed the production and shipment of a coated peanut processing line destined for Nigeria. The client, a company specializing in snack food processing, plans to launch local production of coated peanuts, coated nuts, and similar products.

To enhance production efficiency, ensure product quality, and meet market demand, the client opted for a fully automated production line. This end-to-end solution standardizes operations from roasting and hulling to coating and spraying.

Coated peanut processing line configuration and features

This production line comprises four key pieces of equipment, covering the complete coated peanut production process:

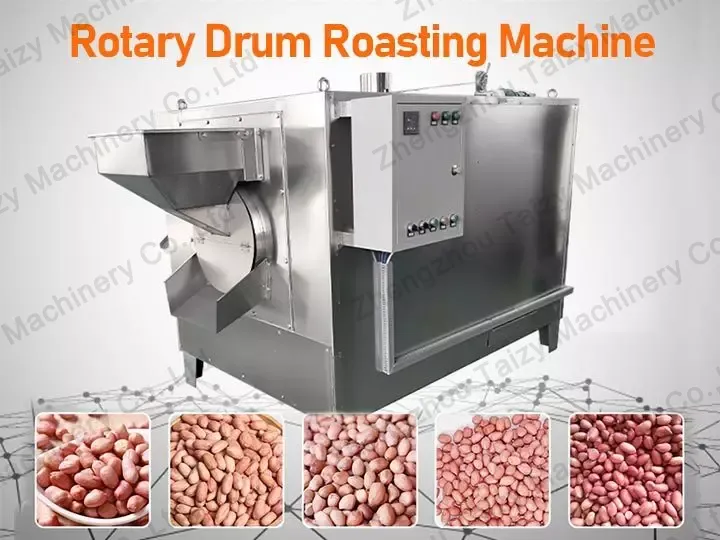

tostador de maní

- Model: TZ-50

- Capacity: 50kg/batch

- Power: 1.1kw

- Heating method: gas heating with automatic temperature setting and constant control

- Material: stainless steel inner chamber for durability and hygiene

The roaster evenly heats peanuts to the required temperature, providing optimal raw material conditions for subsequent peeling and coating processes.

Peladora de maní

- Processing method: dry peeling

- Completion rate: 96%

- Breakage rate: 6%

- Capacity: approx. 200-250kg/h

- Dimensions: 1100×400×1000mm

The peeling machine ensures complete shell removal with minimal breakage, supplying high-quality raw material for coating.

Máquina de recubrimiento de maní

- Capacity: 50-70kg/batch

- Diameter: 1000mm

- Power: 1.1kw, additional heating element power 1000*2

- Heating method: Hot air system

- Features: stainless steel food contact parts, adjustable speed

The coating machine applies sugar powder or flour to the surface of peanuts or other nuts, ensuring uniform and aesthetically pleasing coating. Time and temperature can be flexibly adjusted according to customer requirements.

Liquid sprayer

- Capacity: 50L

- Power: 2.5kW

- Flow rate: 0.2L/min

- Compressed air consumption: 270L/min (Customer-supplied)

The sprayer evenly disperses seasonings or liquid flavorings during coating, further enhancing the finished product’s taste and appearance.

Machines shipping and packaging site

Following assembly, commissioning, and quality inspection of the coated peanut processing line, all equipment underwent professional packaging. Machines were secured in reinforced wooden crates or protective film to ensure safe and stable transportation.

On the shipping day, factory personnel loaded each piece of equipment into containers. Photographs and short videos of the loading process were captured and shared with the client, demonstrating the equipment’s complete and secure transport status.