Rice Bar Production Line | Automatic Snack Bar Machine

| Capacidad de producción | 80–150 kg/h |

| Productos terminados | Rice puff balls, cereal balls, nut balls |

| Product Shape | Spherical, cylindrical, square |

| Forming Type | Turntable molding |

| Materias primas | Puffed grains, nuts, syrup |

| Main Equipment | Puffing machine, sugar cooker, mixer, molding machine, packing machine |

Ahora puede solicitar detalles técnicos a nuestros jefes de proyecto

The fully automatic puffed rice bar production line is specifically designed for the continuous, large-scale production of puffed rice balls, cereal balls, and various puffed cereal confectionery products. It accommodates continuous production demands of approximately 80–150 kg/h.

This integrated system combines puffing, sugar boiling, mixing, molding, and packaging into one unit. It comprehensively meets food processing enterprises’ requirements for efficiency, quality, and diverse product offerings.

Applications of rice bar production line

This puffed rice ball rotary molding line is suitable for processing various grain-based and nut-based snack foods. Typical products include but are not limited to:

- Puffed Rice Balls / Puffed Rice Candy Balls

- Grain Balls, Oat Balls, Corn Balls

- Nut Energy Balls, Protein Balls

- Puffed Rice Candy, Multigrain Candy Products

- Round, Cylindrical, Spherical, and Other Shaped Products

Widely utilized in snack food factories, candy processing plants, grain food enterprises, and export-oriented food processing projects.

Advantages of rice ball rotary molding line

- High automation: continuous operation from ingredient puffing to molding and packaging significantly reduces labor costs.

- Consistent product forming: rotary mold forming ensures uniform size and weight.

- Versatile adaptability: processes diverse grains, nuts, and ingredient combinations.

- Food-grade structural design: critical equipment constructed from stainless steel, meeting food hygiene standards.

- Stable output & high efficiency: ideal for medium-to-large-scale consistent production.

- User-friendly operation & maintenance: clear layout, controllable parameters, and low failure rate.

Snack bar production line process flow

The entire rice bar production line includes the following processes:

- Grain Puffing → Sugar Boiling → Mezclando → Rotary Molding → Packaging

Below is a detailed introduction to each core machine in the production line:

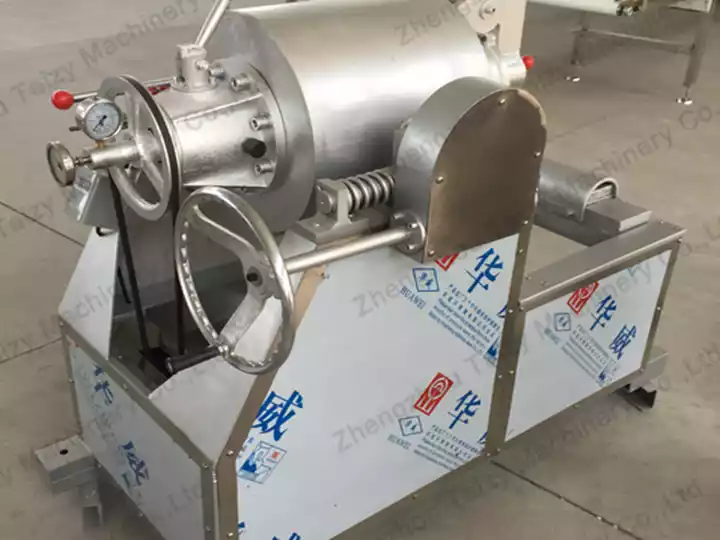

SLP-60 air flow puffing machine

Used for rapid puffing of grains such as rice, corn, wheat, oats, soybeans, and millet. Preserves original flavor and nutrients while ensuring uniform puffing.

| Artículo | Specification |

| Voltaje | 380V / 50Hz |

| Fuerza | 0.75 kW |

| Capacidad | 90–100 kg/h |

| Peso | 500 kg |

| Tamaño | 1600 × 820 × 1370 mm |

TZ-200 jacketed kettle machine

Heating, boiling, and temperature control for syrups, honey, or sugar solutions. Ensures even heating with adjustable temperature settings, suitable for continuous production.

| Artículo | Specification |

| Voltaje | 380V / 50Hz |

| Fuerza | 15 kW |

| Diámetro | Ø840 mm |

| Peso | 480 kg |

| Tamaño | 1470 × 905 × 990 mm |

TZ-15 mixing machine

Thoroughly mix the prepared syrup with puffed grains, nuts, and other ingredients. Equipped with a temperature control system and insulated structure to ensure uniform mixing and prevent clumping.

| Artículo | Specification |

| Voltaje | 380V / 50Hz |

| Fuerza | 1.1 kW |

| Capacidad | 10 kg / batch |

| Tamaño | 700 × 800 × 1200 mm |

HY-MZ100 turnplate molding machine

Core forming equipment achieves automated molding of spherical, circular, cylindrical, and other products through turntable molds. It delivers aesthetically pleasing results with high efficiency.

| Artículo | Specification |

| Voltaje | 380V / 50Hz |

| Fuerza | 2.2 kW |

| Capacidad | 80–150 kg/h |

| Tamaño | 1160 × 1160 × 1380 mm |

TZ-320 package machine

Suitable for high-speed packaging of various regular-shaped foods such as puffed rice balls, puffed rice candy, sacha biscuits, and energy bars. Features attractive seals and strong adaptability.

| Artículo | Specification |

| Voltaje | 220V |

| Fuerza | 2.5 kW |

| Velocidad de embalaje | 50–300 pcs/min |

| Packing Size | L: 50–300 mm / W: 50–310 mm / H: 5–60 mm |

| Tamaño de la máquina | 3800 × 780 × 1500 mm |

Conclusión

The puffed rice bar production line has become an ideal solution for processing cereal balls and puffed confectionery products, thanks to its flexible and diverse molding methods. This production line is suitable for both large-scale, standardized production and can be flexibly configured to meet different product and capacity requirements.

Additionally, we offer a range of peanut and nut snack processing equipment, such as peanut candy processing lines, to meet diverse product forms and market positioning requirements. Feel free to contact us anytime for equipment selection and solution configuration. We provide professional, efficient one-stop services.