Machine de broyage colloïdale en Tanzanie pour la mise à niveau de la production de sauce assaisonnante

Le client tanzanien achetant la machine de broyage colloïdal est une entreprise alimentaire locale spécialisée dans la transformation approfondie de produits agricoles. Elle fabrique principalement diverses sauces d'assaisonnement populaires localement, notamment le beurre de cacahuète, la sauce chili, la pâte de sésame et la sauce tomate.

En utilisant des ingrédients de qualité supérieure et des saveurs traditionnelles, le client a établi une forte réputation sur le marché local. Ses produits sont largement fournis aux supermarchés, restaurants et marchés de gros.

Caractéristiques de la machine de broyage colloïdal

Conçue en acier inoxydable épaissi, la machine colloïdale offre une résistance à la corrosion et un nettoyage facile, respectant pleinement les normes de production de qualité alimentaire. Ses principaux avantages incluent :

- Finesse de broyage élevée : obtient une consistance de pâte exceptionnellement lisse pour les cacahuètes, graines de sésame, fruits, légumes et autres matériaux.

- Vitesse de traitement rapide : fonctionnement continu adapté à la production à grande échelle dans des usines de traitement de sauces de taille moyenne à grande.

- Application polyvalente : une seule unité peut produire divers produits, notamment beurre de cacahuète, sauce chili, pâte de sésame et sauce tomate.

- Fonctionnement stable : utilise des moteurs de qualité supérieure et des disques de broyage de précision pour assurer un fonctionnement prolongé sans surchauffe ni obstruction.

Le déploiement de cette machine de broyage colloïdal améliorera considérablement l'efficacité du traitement, offrira des textures de produit plus lisses et plus cohérentes, et posera une base solide pour accroître la compétitivité sur le marché.

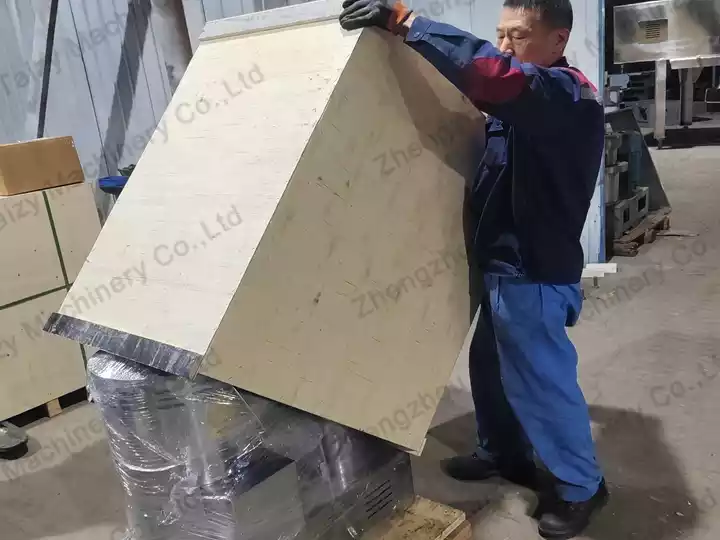

Emballage et expédition

Pour assurer une livraison sûre en Tanzanie, plusieurs mesures de qualité et de transport ont été mises en place avant l'expédition :

- Renforcement anti-choc et fixation sécurisée des composants critiques.

- Protection multicouche utilisant un film anti-humidité et des caisses en bois.

- A effectué des inspections secondaires sur des composants clés tels que les moteurs et les disques de broyage.

- Pièces de rechange incluses, composants résistants à l'usure, et manuel d'utilisation simplifié.

Ces préparations garantissent que les clients peuvent installer, déboguer et commencer la production immédiatement après réception de la machine, améliorant ainsi la commodité opérationnelle.

Nous nous engageons à fournir un support technique continu, une formation opérationnelle et des services de maintenance pour aider le client à construire une entreprise de traitement de sauces d'assaisonnement plus compétitive.