Mehlbeschichtete Erdnuss-Produktionslinie | Erdnuss-Beschichtungs-Verarbeitungsanlage

| Erdnussröstmaschine | 50-500kg/h |

| Erdnuss-Schälmaschine | 200-1000kg/h |

| Erdnussbeschichtungsmaschine | 30-300kg/h |

| Frittiermaschine | 500kg/h |

| Schwenkofen | 80-300kg/h |

| Würzmaschine | 300-1500kg/h |

| Kühlmaschine | 80-100kg/h |

| Verpackungsmaschine | 50-100 Beutel/min |

Sie können jetzt unsere Projektmanager nach technischen Details fragen

Die Produktionslinie für beschichtete Erdnüsse ist speziell für die großtechnische, vollständig automatisierte Verarbeitung von beschichteten Erdnüssen und anderen beschichteten Hülsenfrüchte-Snacks konzipiert. Sie verwendet Erdnüsse, Ackerbohnen, Cashewnüsse, Macadamianüsse und andere Zutaten als Hauptrohstoffe und durchläuft Prozesse wie Rösten, Schalen, Beschichten, Backen, Würzen, Abkühlen und Verpacken.

Das Endprodukt weist eine gleichmäßige Beschichtung, ein ansprechendes Aussehen und eine knusprige Textur auf, was es auf dem Markt sehr beliebt macht. Es ist ideal für Investitionen und den Einsatz durch mittelgroße bis große Lebensmittelverarbeitungsbetriebe und Snackfood-Unternehmen.

Diese Produktionslinie für beschichtete Erdnüsse bietet einen hohen Automatisierungsgrad, sodass in der Regel nur 4 Arbeiter benötigt werden, um die gesamte Linie zu bedienen. Dies senkt nicht nur effektiv die Arbeitskosten und verringert die Produktionsausgaben, sondern steigert auch erheblich die Produktionseffizienz und Produktqualität.

Anwendung der Produktionslinie für Erdnussbeschichtungen

- Erdnussprodukte: zuckerbeschichtete Erdnüsse, pulverbeschichtete Erdnüsse, Honigerdnüsse, würzige Erdnüsse, Senferdnüsse, Schokoladenerdnüsse, Erdnussburger usw.

- Bohnenprodukte: beschichtete Ackerbohnen, beschichtete grüne Bohnen, beschichtete Erbsen, beschichtete Edamame usw.

- Nussprodukte: beschichtete Cashewnüsse, Macadamianüsse, Sonnenblumenkerne usw.

- Vielfältige Snacks: können erweitert werden um würzige knusprige Chips, gepuffte Lebensmittel, Schokoladenbohnen, mit Meeresfrüchten beschichtete Snacks und andere Spezialsnacks.

Vorteile der Erdnussbeschichtungsproduktionslinie

- Die Prozessparameter der gesamten Produktionslinie für beschichtete Erdnüsse (Temperatur, Geschwindigkeit, Winkel usw.) können frei angepasst werden, um eine kontinuierliche Produktion mit minimaler manueller Aufsicht zu erreichen.

- Die Beschichtung ist gleichmäßig und konsistent in der Dicke, was zu einer glatten und ansprechenden Oberflächenbeschaffenheit, einer knusprigen Textur und hohen Wiederkaufquoten führt.

- Angepasste Produktionskapazitäten können auf die Bedürfnisse sowohl von kleinen als auch von großen Verarbeitungsbetrieben zugeschnitten werden.

- Alle Teile, die mit Lebensmitteln in Kontakt kommen, bestehen aus Edelstahl in Lebensmittelqualität, der langlebig, leicht zu reinigen und konform mit den Lebensmittelsicherheitsstandards ist.

- Einstellbare Parameter umfassen Neigungswinkel, Heizmethoden und Geschwindigkeit, mit optionalen Zubehörteilen wie Sprühgunsystemen und Staubabsaugsystemen.

- Geeignet nicht nur für Erdnüsse, sondern auch für die Verarbeitung verschiedener Hülsenfrüchte und Nüsse, um den vielfältigen Marktanforderungen gerecht zu werden.

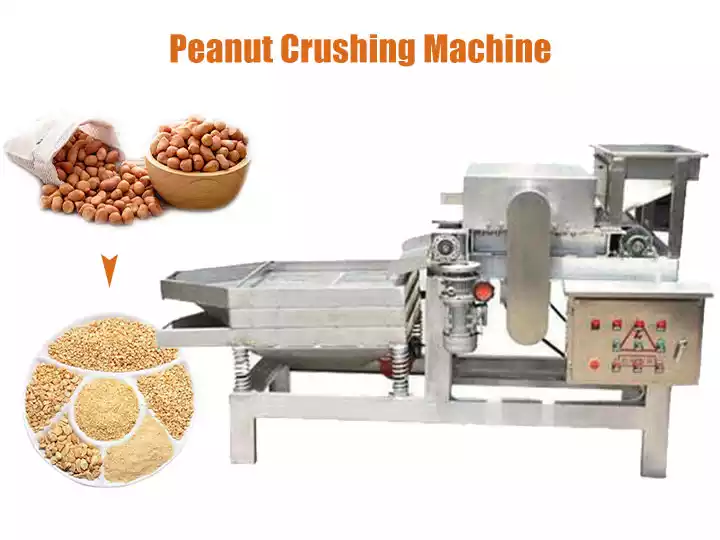

Hauptgeräte der beschichteten Erdnussproduktionslinie

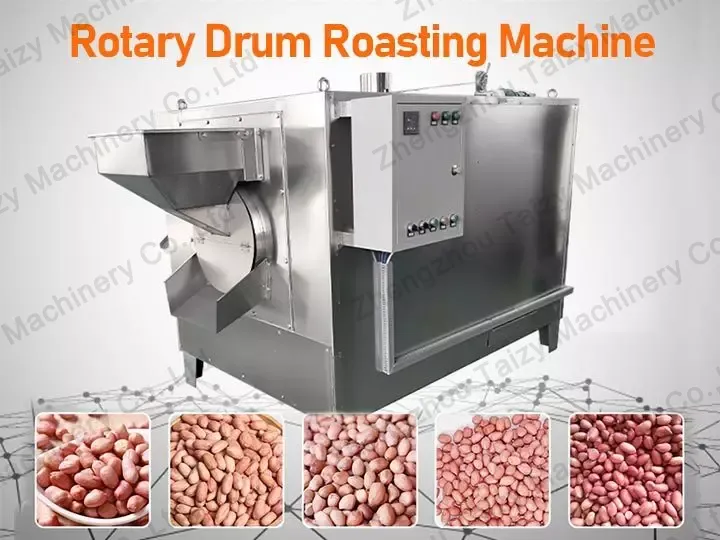

Erdnussröstmaschine

Die Erdnussröstmaschine wird verwendet, um Erdnusskerne zu rösten. Das Rollendesign sorgt dafür, dass die Erdnüsse gleichmäßig erhitzt werden und nicht leicht anbrennen. Außerdem kann die Bruchrate der Erdnüsse verringert werden.

Gleichzeitig wird die Feuchtigkeit der Erdnüsse auf weniger als 5 % reduziert. Sie können verschiedene Heizmethoden wie elektrische Heizung, Gasheizung und Kohlenheizung wählen.

| Modell | Abmessung (mm) | Kapazität (kg/h) | Leistung (kw) | Strom Heizung (kW) | Gasheizung (kg) |

| TZ-1 | 3000*1200*1700 | 80-120 | 1.1 | 18 | 2-3 |

| TZ-2 | 3000*2200*1700 | 180-250 | 2.2 | 35 | 4-6 |

| TZ-3 | 3000*3300*1700 | 280-350 | 3.3 | 45 | 6-8 |

| TZ-4 | 3000*4400*1700 | 380-450 | 4.4 | 60 | 8-10 |

| TZ-5 | 3000*5500*1700 | 500-650 | 5.5 | 75 | 10-12 |

Erdnussschälmaschine

Die trockene Erdnuss-Schälmaschine kann die Erdnussschale vom Erdnusskern trennen. Die Schälrate der Maschine liegt über 96 %.

| Komplettpreis | ≥96% |

| Dimension | 1100*400*1000mm |

| Kapazität | 200-250kg/h |

Maschine zur Herstellung beschichteter Erdnüsse

Die Erdnussbeschichtungsmaschine ist die Hauptmaschine in der Erdnüsse in Mehl beschichteten Produktionslinie. Die Beschichtungsmaschine sorgt dafür, dass das Material unter dem Einfluss der Zentrifugalkraft im Inneren der Maschine rollt und reibt.

Dann wird der Erdnusskern gleichmäßig mit Puderzucker vermischt, und die Oberfläche der mit unserer Maschine hergestellten beschichteten Erdnüsse ist glatt.

| Leistung | 1,1 kW/380 V, 220 V |

| Gewicht | 180kg |

| Dimension | 1200*1000*1300 |

| Durchmesser | 1000 mm |

Erdnuss-Schwingofen

Der Erdnuss-Schwenk-Röster ist eine Maschine, die die umhüllten Erdnüsse mittels elektrischer und Gasheizung röstet. Diese Maschine ist einfach zu bedienen. Arbeiter müssen nur die Erdnüsse in den Erdnussröster geben. Dann 15 Minuten warten, um sie aus dem Ofen zu nehmen.

| Leistung | 25,75 kW |

| Stromspannung | 380 V/50 Hz |

| Größe | 2200*2000*1500mm |

| Heizleistung | 25 kW |

| Schwungkraft | 0,75 kW |

| Gewicht | 500kg |

| Geschwindigkeit | 40–60 Mal/Minute |

Erdnuss-Würzmaschine

Die Erdnuss-Gewürzmaschine kann Erdnüsse und Gewürze gut mischen. Unsere Maschine kann mit einem externen Sprühgerät oder manuellem Materialgießen verbunden werden. Benutzer können je nach Bedarf die erforderlichen Gewürze in die Maschine geben.

| Leistung | 1,1 kW/380 V |

| Gewicht | 150kg |

| Dimension | 1000*800*1300mm |

| Laufdurchmesser | 1000 mm |

| Kapazität | 300kg/h |

Erdnusskühlmaschine

Der Erdnusskühler ist eine Maschine, mit der die Temperatur der verpackten Erdnüsse gesenkt wird. Dies dient der Vorbereitung für das anschließende Verpacken. Die Maschine besteht hauptsächlich aus dem Kühlteil und dem Speicherteil.

| Modell | Kapazität (kg/h) | Lüfterleistung (kW) | Spannung/Frequenz | Abmessung (mm) |

| TP-1 | 200-300 | 1.1 | 380 V/220 V, 50 Hz | 1300*600*600 |

Verpackungsmaschine für Erdnussgranulat

Die Verpackungsmaschine für Erdnussgranulate eignet sich zum Verpacken von Erdnussgranulaten, Popcorn, verschiedenen Nüssen und anderen granularen Materialien. Sie ist auch die letzte Maschine in der Produktionslinie für beschichtete Erdnüsse.

| Taschenstil | Rückensiegel (anpassbar) |

| Verpackungsgeschwindigkeit | 37–72 Beutel/Minute oder 50–100 Beutel/Minute |

| Taschenlänge | 30-180mm |

| Füllbereich | 22-220 ml |

| Stromverbrauch | 1,8 kW |

| Gewicht | 250kg |

| Abmessungen | 650*1050*1950mm |

| Kartongröße | 1100*750*1820mm |

Zusammenfassung

Die Produktionslinie für zuckerbeschichtete Erdnüsse muss gemäß den spezifischen Anforderungen des Kunden in Bezug auf die Ausbringung und die Größe des Produktionsbetriebs angepasst werden. Als vertrauenswürdiger Anbieter von Erdnussverarbeitungsmaschinen bietet unser Unternehmen eine Reihe von maßgeschneiderten Dienstleistungen wie perfekten Prozessablauf und Geräteanpassung an.

Wenn Sie effiziente, sichere und anpassbare Geräte für die Produktionslinie von beschichteten Erdnüssen suchen, zögern Sie bitte nicht, uns für detaillierte Spezifikationen und maßgeschneiderte Lösungen zu kontaktieren.