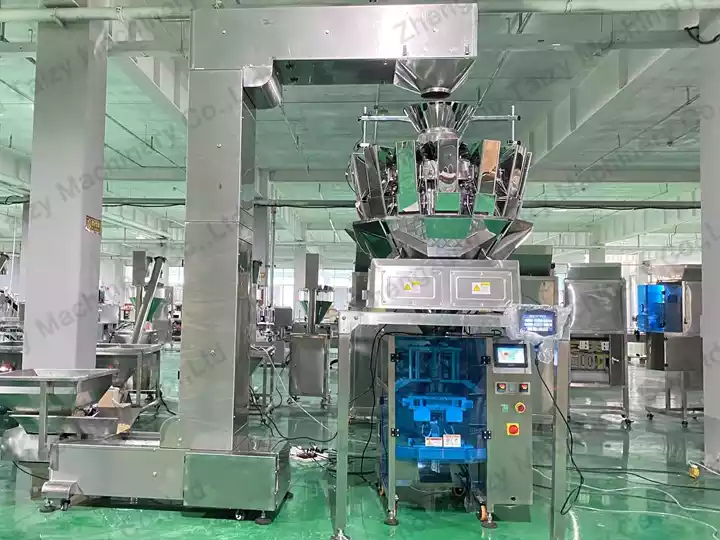

10 Heads Weighing Packaging Machine | Weigher Packing Machine

| Modell | TH-720 |

| Bag length | 100-500mm (L) |

| Bag width | 180-350mm (W) |

| Max roll film width | 720mm |

| Packing speed | 5-50 bags/min |

| Measuring range | 6000ml (Max) |

| Air pressure | 0.65 Mpa |

| Gas consumption | 0.4 m³/min |

| Power voltage | 220VAC/50Hz |

| Dimension (L×W×H) | 1780×1350×1950mm |

Sie können jetzt unsere Projektmanager nach technischen Details fragen

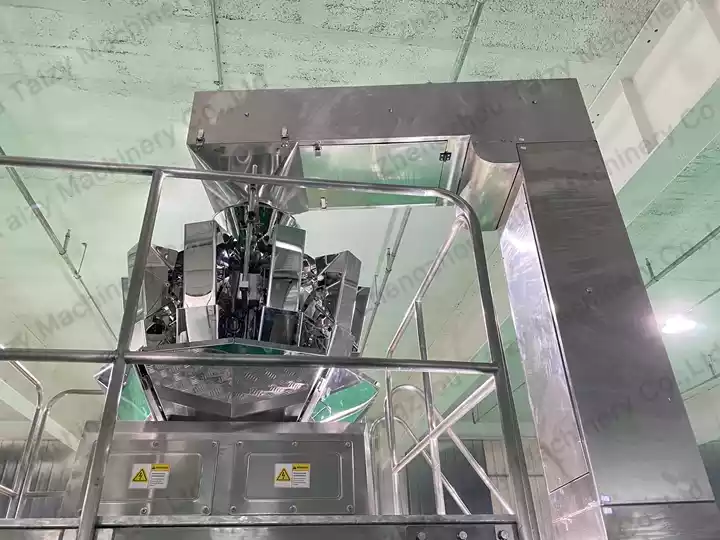

The 10-Head Weighing Packaging Machine is specifically designed for granular, powdered, and large-block materials. This machine integrates a ten-head electronic combination scale with a vertical packaging machine, achieving fully automated operations from weighing, filling, bag forming, sealing, and cutting, to product conveying.

Equipped with a PLC programmable control system and a large touchscreen interface, the machine achieves packaging speeds up to 50 bags per minute. Utilizing servo control and high-precision electronic scales, it delivers accuracy within ±1%. This ensures aesthetically pleasing, dimensionally precise packaging while accommodating diverse materials and packaging formats.

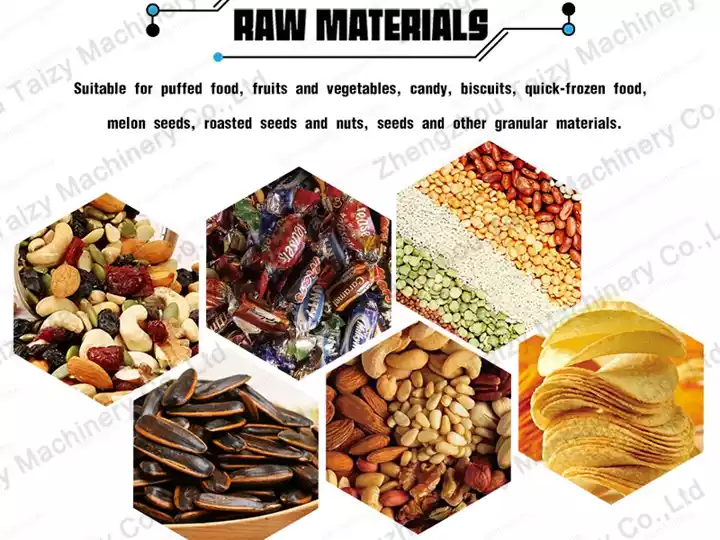

Applications of weighing packaging machine

- Food industry: automatic weighing and packaging of snack foods such as puffed snacks (e.g., potato chips, rice crackers, shrimp sticks), large-shell nuts (walnuts, pistachios), candies, melon seeds, small cookies, fruit/vegetable chips, chocolate, preserved plums, roasted nuts, and jellies.

- Non-food industry: quantitative packaging of granular, block, and strip-shaped materials for pet food and small hardware components.

- Powder and liquid materials: suitable for powdered and liquid paste materials (e.g., milk powder, soybean powder).

Multihead weigher filling machine features

- High precision and efficiency: each of the ten heads in the electronic combination scale independently senses materials, automatically combining them to achieve the closest possible target weight ratio. Accuracy reaches ±1%, with packaging speeds ranging from 5 to 50 bags per minute.

- Fully automated integration: automatically completes hopper lifting, weighing, bag forming, filling, sealing/cutting, and coding operations, reducing manual intervention and error rates.

- Simple operation: features an oversized color touchscreen with three language interfaces for quick setup of packaging length, speed, and cutting methods. Deviation adjustments require no tools.

- High stability and hygiene: entirely constructed of stainless steel for cleanliness and hygiene. Enclosed mechanisms effectively prevent dust ingress. Independent pneumatic and electrical circuitry ensures low noise and stable electrical performance.

- High flexibility: configurable with Z-type elevators, single/continuous bag cutting, and perforation devices to accommodate both fragile and non-fragile materials.

Automatic 10-head packing machine specifications

| Modell | TH-720 |

| Bag length | 100-500mm (L) |

| Bag width | 180-350mm (W) |

| Max roll film width | 720mm |

| Packing speed | 5-50 bags/min |

| Measuring range | 6000ml (Max) |

| Air pressure | 0.65 Mpa |

| Gas consumption | 0.4 m³/min |

| Power voltage | 220VAC/50Hz |

| Leistung | 5Kw |

| Dimension (L×W×H) | 1780×1350×1950mm |

Machine structure and working principle

Z-Type material elevator

- Features 304 stainless steel buckets for uniform material discharge, with rubber-lined edges to prevent fine particles from jamming.

- Equipped with an adjustable vibration mechanism to ensure smooth material flow into the transfer box.

- Independent electrical cabinet and snap-on design facilitate maintenance and chain tension adjustment.

10-Head electronic combination weigher

- Each head features independent electronic weighing with precision sensors for material monitoring.

- Maximum capacity: 6kg. Vibrator assists material discharge.

- Equipped with a 9.7-inch PLC touchscreen supporting multi-language operation interfaces.

Vertical pouch filler

- Servo-controlled for high-precision bag forming and cutting.

- Adjustable packaging speed, bag length, and cutter temperature; supports single-bag or continuous-bag cutting.

- Automatic alarm diagnostics enhance production safety.

Electronic scale work platform

- Four-sided anti-slip guardrails with four removable legs for enhanced safety.

- Provides stable support for easy operation and maintenance.

Discharge conveyor belt

- Features adjustable transmission speed.

- Constructed from PVC with wheels for easy mobility.

Workflow

- Materials are conveyed via a Z-type elevator to the ten-head electronic scale.

- Each weighing head operates independently, automatically combining the closest ratio to the target weight.

- Materials are then released from the weighing hoppers into the vertical packaging machine, where bag forming, filling, sealing, and discharge are completed, achieving fully automated packaging.

Abschluss

If your product specifications, production capacity requirements, or budget differ, we can also provide more suitable solutions. For example, 4-head weighing packaging machines, turntable-type granular packaging machines, and other customized equipment can meet diverse material and packaging format needs.

Feel free to contact us anytime for professional selection advice and detailed solutions. We will tailor an efficient and reliable packaging production line specifically for you.