Leverans av 4 set med jordnötter röda hudborttagare till Spanien slutförd

Kiwanda chetu kimekamilisha na kutuma seti 4 za mashine za kuondoa ngozi nyekundu za karanga. Mteja yuko katika eneo kuu la kilimo la kusini-mashariki mwa Uhispania, na ni biashara ya chakula ya ukubwa wa kati inayojishughulisha na siagi ya karanga, karanga zilizokaangwa na bidhaa za karanga za papo hapo.

Information om kundens bakgrund

Kundens företag bearbetar 5 000 ton jordnötsråvaror årligen, och dess produkter levereras huvudsakligen till högklassiga stormarknader och hälsokostkedjor i EU.

Under de senaste åren, med EU:s stränga krav på livsmedelssäkerhetscertifiering, samt den växande efterfrågan från konsumenter på tillsatsfria jordnötsprodukter med låg brustakt, behöver företaget brådskande uppgradera den traditionella manuella bearbetningsmetoden.

Krav på maskiner

Vifaa vya mteja vilitegemea uchambuzi wa nusu-automated au wa mikono, ukiwa na kiwango cha kutokomeza uchafu cha takriban 85% na kiwango cha kuvunjika cha 8%-10%.

Med tillväxten av beställningar behöver kunden uppnå en stabil leverans av 5 000 ton råmaterial under hela året, och samtidigt behöver de minska manuell intervention för att sänka produktionskostnaderna.

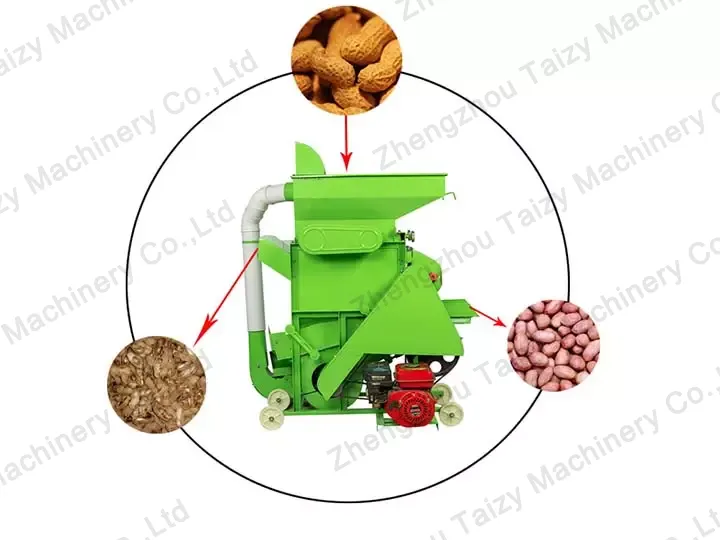

Lösning för maskin för att ta bort röd hud från jordnötter

- Kombination av differential rullfriktion och vindsortering för att uppnå en borttagningsgrad på över 98% utan kemiska tillsatser.

- Brytningsgraden kontrolleras inom 3,5%, vilket uppfyller de stränga kraven på jordnötsintegritet för bageriprodukter.

- Inbyggd suganordning undviker produktionsföroreningar och uppfyller hygienstandarderna för EU:s livsmedelsbearbetningsverkstad.

- Det stöder snabb utbyte av siktmask för att möta olika specifikationer av jordnötsbearbetningsbehov, och den dagliga bearbetningskapaciteten för en enda maskin kan uppgå till 30 ton.

Mteja anatarajia ongezeko la 20% la thamani ya mauzo ya kila mwaka baada ya mashine ya kumenya karanga kuingizwa katika uzalishaji, na anapanga kukuza mistari ya biashara inayohusiana kama vile mafuta ya zeituni na bidhaa za karanga. Ikiwa pia unahitaji mashine za kusindika karanga, tafadhali wasiliana nasi wakati wowote.