Mafuta ya Karanga | Kichocheo cha Mafuta ya Karanga

| Mfano | TZ-80 |

| Bonyeza Kipenyo | 80 mm |

| Bonyeza Kasi | 35r/dak |

| Injini | 4kw |

| Pumpu ya Utupu | 0.55kw |

| Nguvu ya Kupokanzwa | 2.2kw |

| Uwezo | 80-120kg / h |

| Uzito | 850kg |

| Ukubwa | 1.7*0.11*1.6m |

Sasa unaweza kuwauliza wasimamizi wetu wa mradi kwa maelezo ya kiufundi

Extractor ya mafuta ya karanga ya screw ya kiotomatiki imeundwa kwa karanga, soya, mbegu za mkaratusi, mbegu za alizeti na mazao mengine ya mafuta yenye uzalishaji wa mafuta chini ya 40%. Ikilinganishwa na njia za jadi za uchimbaji wa mafuta, mashine hii inaboresha ufanisi wa uzalishaji wa mafuta kwa 35%-50% na kupunguza matumizi ya nishati kwa 60%.

Den är kompatibel med mer än 20 typer av oljeväxter samtidigt och garanterar oljans renhet med en livsmedelsklassad rostfri stålprocess. Med sin kompakta struktur och enkla drift kan den användas i stor utsträckning i familjeverkstäder, små oljemöllor och oljeprocesseringsprojekt i det tidiga skedet av verksamheten.

Fördelar med jordnötsskrueoljeutvinningsmaskin

- Mchango mdogo: ni mita za mraba 10-20 tu, inafaa kwa maeneo mbalimbali.

- System ya kupigia mafuta yenye ufanisi wa juu: muundo ulioboreshwa wa chumba cha kupigia mafuta huongeza shinikizo la ndani na kuboresha kwa kiasi kikubwa ufanisi wa kupigia mafuta.

- Aina mbalimbali za malighafi zinazoweza kutumika: zaidi ya aina 20 za malighafi za mafuta zinaweza kusindika ili kukidhi mahitaji mbalimbali ya uzalishaji.

- Nguvu ya usindikaji: inaweza kusindika kilo 500 za malighafi kwa saa, na ni rahisi kuendesha, mtu mmoja tu anaweza kukamilisha uzalishaji.

- Muundo thabiti na wa kudumu: extractor yote ya mafuta ya karanga imeundwa kwa chuma cha kaboni cha ubora wa juu, kinachostahimili kuvaa na kudumu, kinasaidia uendeshaji wa muda mrefu bila kukatika.

- Mafuta mengi: kiwango cha mafuta kinaweza kufikia takriban 50%, kiwango cha mafuta kilichobaki kwenye keki kavu ni chini ya 8%, na kiwango cha matumizi ya mafuta ni cha juu.

Tillämpningsområde för skruvpressmaskin för olja

Mashine hii ya kutoa mafuta ya karanga inafaa kwa aina mbalimbali za mbegu za mafuta ya mboga na karanga, ikiwa ni pamoja na lakini sio tu: mbegu za haradali, mbegu za alizeti, mbegu za mafuta ya rapeseed, soya, mbegu za castor, karanga za shea, nazi au mbegu za copra, mbegu za neem, mbegu za pamba, mbegu za jatropha, ganda la mahindi, mbegu za flax, ganda la palm, karanga, mbegu za sesamu, na kadhalika.

Om du är osäker på om dina råvaror är lämpliga, tveka inte att kontakta oss. Vi kan erbjuda dig en gratis tjänst för testning av råvaror för att hjälpa dig utvärdera oljeproduktionsresultatet.

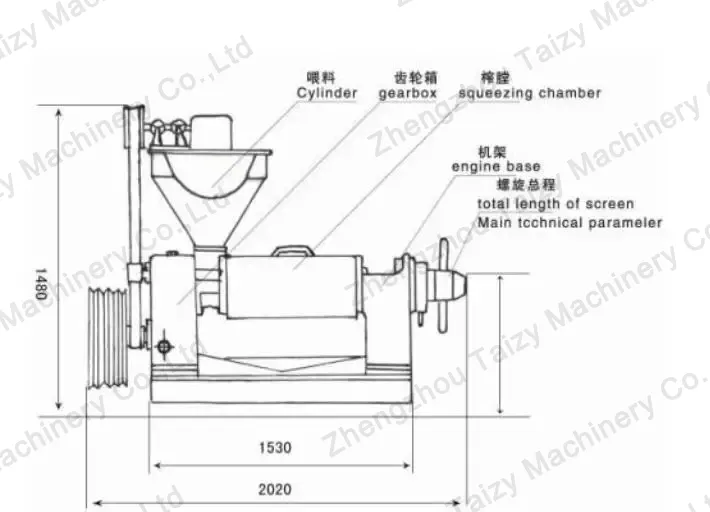

Muundo wa extractor wa mafuta ya screw na kanuni ya kufanya kazi

Extractor wa mafuta ya karanga hasa inajumuisha sanduku la udhibiti wa kiotomatiki, sehemu ya kupasha joto na kushinikiza, kifaa cha kurekebisha, sehemu ya kuzunguka na mfumo wa filtration wa vacuum. Sehemu zote hufanya kazi pamoja ili kutimiza mchakato wa kupitisha mafuta kiotomatiki na kwa ufanisi kutoka kwa kulisha malighafi, kupasha joto, na kushinikiza hadi kuchuja mafuta.

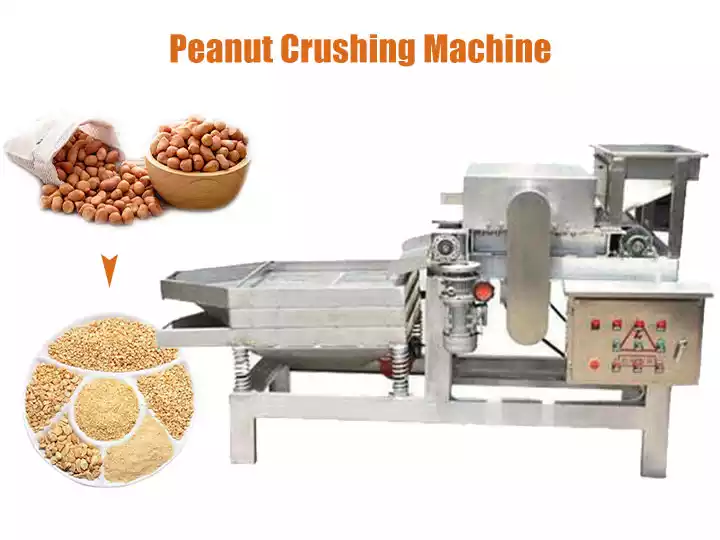

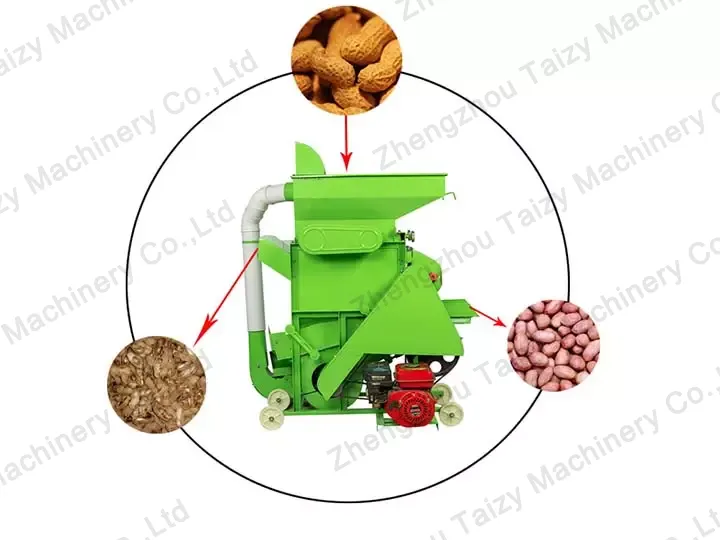

- Förbehandling av råmaterial: beroende på oljeinnehållet och de fysiska egenskaperna hos oljeväxterna, behöver de vanligtvis genomgå rengöring, torkning, krossning, valsning av embryo, ångning och temperering samt andra förbehandlingssteg.

- Kuingiza: karanga zilizotayarishwa awali na malighafi nyingine zinamwagika kwenye hopper.

- Propulsion och tryckhöjning med skruv: drivet av skruvaxeln, rör sig materialet framåt; när utrymmet i presskammaren gradvis minskar, ökar materialets densitet och det interna trycket stiger.

- Utekelezaji wa mafuta na grease: chini ya athari ya joto na shinikizo kubwa na joto la msuguano, muundo wa seli wa nyenzo za mafuta unaharibiwa na mafuta na grease zinach released.

- Filtration ya vacuum: mafuta yaliyotolewa yanapita kupitia mfumo wa filtration ya vacuum ili kuondoa mabaki na uchafu na kupata mafuta safi ya kula.

- Mkusanyiko wa bidhaa zilizokamilika: mafuta ya kula yaliyosafishwa yanaweza kukusanywa na kutumika.

Parametrar för jordnötsolja extraktionsmaskin

| Mfano | TZ-60 | TZ-70 | TZ-80 | TZ-180 | TZ-125 |

| Bonyeza Kipenyo | 55 mm | 65 mm | 80 mm | 100 mm | 125 mm |

| Bonyeza Kasi | 64r/dak | 38r/dak | 35r/dak | 37r/dak | 34r/dak |

| Injini | 202kw | 3 kw | 4kw | 7.5kw | 15kw |

| Pumpu ya Utupu | 0.75kw | 0.75kw | 0.55kw | 0.75kw | 0.75kw |

| Nguvu ya Kupokanzwa | 0.5kw | 1.1kw | 2.2kw | 3 kw | 3.75kw |

| Uwezo | 40-60kg / h | 50-70kg / h | 80-120kg / h | 150-230kg / h | 300-350kg / h |

| Uzito | 240kg | 280kg | 850kg | 1100kg | 1400kg |

| Ukubwa | 1.2*0.48*1.1m | 1.4*0.5*1.2m | 1.7*0.11*1.6m | 1.9*1.2*1.3m | 2.6*1.3*2.3m |

Ni karanga gani iliyo bora zaidi kwa uchimbaji wa mafuta?

- Fikiria ukubwa wa punje ya karanga. Ikiwa punje ya karanga ni kubwa sana, haitatoshea kupitia ufunguzi wa malisho wa mashine ndogo za kukandamiza mafuta. Kinyume chake, ikiwa punje ni ndogo sana, kasi ya chini ya mto itakuwa kubwa sana, ambayo inaweza kuzuia mavuno ya mafuta. .

- Angalia ikiwa punje ya karanga ni mbichi. Ni muhimu kwamba karanga zinazotumiwa kwa uchimbaji wa mafuta zisiwe na ukungu, kwani kokwa zenye ukungu zina aflatoksini, kasinojeni yenye nguvu.

- Chunguza aina mbalimbali za kokwa za karanga. Kuna aina kadhaa za karanga, ikiwa ni pamoja na karanga za kawaida, karanga za lulu, karanga za nafaka nyingi, na karanga za joka. Aina ya kawaida ndiyo inayofaa zaidi kwa uchimbaji wa mafuta, ikijivunia maudhui ya mafuta ya 52-54%.

Jinsi ya kuanza biashara ya uchimbaji mafuta ya karanga?

- Fanya uchambuzi wa kina wa soko. Ni muhimu kuamua kama karanga zinalimwa katika eneo hilo, kutathmini ubora wa karanga, kuelewa mahitaji ya ndani ya mafuta ya karanga, na kutathmini viwango vya mapato ya wakazi.

- Välj en lämplig plats för att ställa upp en mafuta ya karanga biashara ya uchimbaji. Baada ya hapo, pata leseni ya biashara inayohitajika kutoka kwa idara husika ya serikali.

- Nunua vifaa vya mashine ya kusindika mafuta ya karanga. Ikiwa unataka kuanza kiwanda cha mafuta ya karanga, basi mafuta ya karanga haitoshi. Unahitaji mashine ya kukoboa karanga, mashine ya kumenya karanga, uchimbaji wa mafuta ya karanga, mashine ya kujaza karanga, na vifaa vingine vinavyohusiana

- Soko mafuta yako ya karanga. Hatimaye, unahitaji kutafuta njia za mauzo ili kuuza mafuta yako ya karanga.

Vi välkomnar förfrågningar på engelska, franska, arabiska, spanska, ryska och många andra språk. Vårt professionella team kommer att svara dig inom en arbetsdag. Om du är intresserad av vår jordnötsolja extraktionsmaskin, tveka inte att kontakta oss!