Mstari wa Uzalishaji wa Vibao vya Nafaka vya Kiotomatiki | Mashine ya Kutengeneza Pipi ya Karanga

| Bidhaa Zinazofaa | Karanga ya Kukandamizwa, Pipi ya Mdingasisi, Vibandiko vya Karanga, Vibandiko vya Nafaka, Vibandiko vya Nguvu |

| Uwezo wa Uzalishaji | 300–400 kg/h |

| Ugavi wa Nguvu | 220V / 380V, 50Hz |

| Njia ya Joto | Kupasha kwa umeme (kupasha gesi kwa hiari) |

| Ukubwa wa Bershi | Inayoweza kubadilishwa, inasaidia maumbo na ukubwa mbalimbali |

| Nyenzo zinazogusa chakula | chuma cha pua 304 |

| Kiwango cha Uendeshaji | Moja kwa moja kabisa, inahitaji tu waendeshaji 1–2 |

Sasa unaweza kuwauliza wasimamizi wetu wa mradi kwa maelezo ya kiufundi

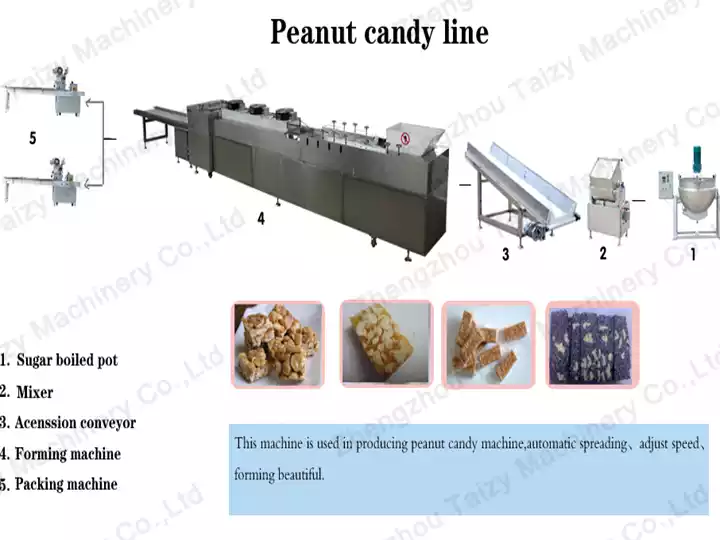

Laini ya uzalishaji yenye ufanisi wa 300-400kg/h iliyotengenezwa kwa njia ya kiotomatiki kabisa imeundwa mahsusi kwa utengenezaji wa kiwango kikubwa wa pipi za karanga, vibandiko vya nafaka, na vyakula vya vitafunwa vya afya. Mchakato mzima wa uzalishaji — kuanzia mchanganyiko wa malighafi, kuchemsha na kuoka, kuunda na kusaga, kukata kwa urefu maalum, kupoza, hadi ufungashaji wa mwisho — unafanya kazi kwa mfululizo. Mtiririko wa kazi umeunganishwa kwa karibu, ukihakikisha ufanisi wa juu na utulivu wa kipekee.

Imewekwa na mfumo wa udhibiti mwenye akili, laini inaruhusu kurekebisha kwa usahihi vigezo muhimu vya mchakato ili kuhakikisha muundo thabiti wa bidhaa na muonekano wa umaalumu. Muundo wake wa moduli wenye kubadilika unahitaji mapishi mbalimbali na maumbo ya bidhaa, kuwezesha ukuzaji wa haraka wa ubunifu wenye thamani ya juu ili kuongeza ushindani wa soko.

Matumizi ya laini ya uzalishaji wa pipi za karanga

- Uzalishaji wa pipi za karanga na vibandiko vya mlo: pipi za karanga za kitamaduni na za uvumbuzi ikiwa ni pamoja na karanga ya kukandamizwa, pipi ya mzingi, pipi za karanga, na chikki.

- Vibandiko vya nafaka na vyakula vya nishati: vyakula vya afya kama vibandiko vya oats, vibandiko vya nafaka, vibandiko vya nishati, vibandiko vya protini, na vibandiko za kubadilisha mlo.

- Makampuni yanayochakata vyakula vya vitafunwa: inafaa kwa viwanda vya pipi, mimea ya vyakula vya vitafunwa, na vituo vya usindikaji wa vyakula vya nafaka.

- Miradi ya kuanzisha na kupanua: bora kwa biashara ndogo hadi za kati za chakula au wajasiriamali wanaoingia kwenye masoko ya pipi za karanga na vibandiko vya nafaka.

Vipengele vya mstari wa uzalishaji wa nafaka za karanga

- Inayoweza kuboreshwa kwa kiwango kikubwa: inabadilika kwa urahisi muundo wa laini ya uzalishaji na usanidi wa vifaa kulingana na aina za bidhaa na mahitaji ya uwezo.

- Viwango vya usalama vya daraja la chakula: sehemu zote zinazogusa nyenzo zimetengenezwa kwa chuma cha pua 304, zikitimiza mahitaji ya usafi na usalama wa vyakula.

- Uzalishaji wa hali ya juu: uendeshaji wa mfululizo kote laini unahakikisha uendeshaji rahisi, ukihitaji tu mtoaji mmoja kwa ufuatiliaji wa uzalishaji.

- Uzalishaji thabiti na ufanisi mkubwa: inaunga mkono uzalishaji wa kuendelea kwa muda mrefu ili kutimiza mahitaji ya agizo nyingi za kiwango kikubwa.

- Urekebishaji wa haraka kwa soko: kubadilisha haraka aina za bidhaa kwa kurekebisha mapishi na vimo, kupunguza gharama za jaribio la uzalishaji.

Complete peanut candy making process

The complete peanut cereal bar production line process involves baking, peeling, boiling sugar, mixing, briquetting, cooling, cutting, and packaging.

Laini nzima ya uzalishaji wa vibandiko vya nafaka inajumuisha mashine ya kukaanga karanga, mashine ya kusugua karanga, sufuria yenye koti, mashine ya kuunda na kukata pipi za karanga, na mashine ya kufunga pipi za karanga.

Jinsi ya kufanya karanga brittle?

Kuchoma

- Karanga kwanza huokewa ili kuongeza harufu na kuboresha muundo, jambo muhimu kwa pipi za karanga zenye ubora wa juu.

- Biashara ya biashara mashine ya kukaanga karanga inahakikisha upasha joto sawa kupitia mzunguko wa drum unaoendelea, kuzuia kuchoma kwa sehemu moja.

- Roaster inasaidia chaguzi za kupasha joto kwa umeme na gesi na inafaa kwa karanga, mbegu za mzingirizi, korosho, mlozi, na karanga nyingine.

Kuchubua

- Baada ya kuoka, karanga husafishwa kuondoa ngozi nyekundu, ambayo inaweza kusababisha uchungu ikiwa itabaki.

- The mashine ya kumenya karanga inatumia msuguano wa rinkia kwa ajili ya uondoaji wa ngozi kwa ufanisi.

- Ufanisi wa kusugua inafikia hadi 98%, kwa kiwango cha chini cha kuvunika ili kudumisha uadilifu wa kiini.

Kutengeneza syrup

- Sukari inayeyushwa kuwa sirapu kwa kutumia sufuria yenye koti, ikitengeneza msingi wa kuunganisha wa pipi za karanga.

- Mfumo wa kuchanganya uliojengewa ndani unazuia kushikamana na kuhakikisha upasha joto wa usawa.

- Viambato vya ziada kama asali vinaweza kuongezwa wakati wa mchakato huu ili kuboresha ladha.

Kuchanganya

- Karanga zilizookwa na sirapu zimeshakamuliwa vizuri ili kupata kufunikwa sawa.

- Mchanganyiko unaoweza kupindishwa unaiwezesha kutokwa kwa urahisi na uendeshaji laini.

- Lining ya daraja la chakula ndani inazuia nyenzo kushikamana na drum ya kuchanganya wakati ikidumisha viwango vya kelele vya chini.

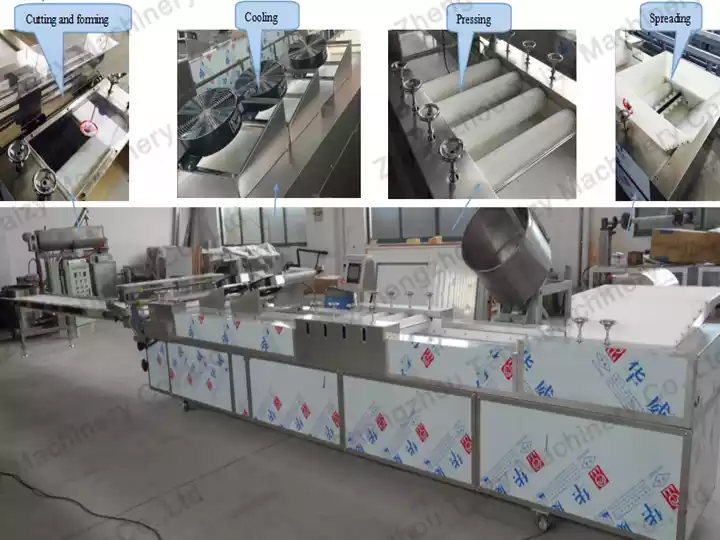

Kutengeneza na kukata

- Mchanganyiko wa nyenzo unaingizwa katika mashine ya kutengeneza na kukata karanga brittle, kitengo kikuu cha laini ya uzalishaji.

- Mfumo wa kusongesha umepanga mchanganyiko kuwa slab za gorofa zenye unene thabiti.

- Mfumo wa kupoza kwa hewa husaidia kutuliza umbo kabla ya kukata.

- Kitengo cha kukata kinakata slab kuwa vibandiko au vifungu vinavyolingana, kwa kasi inayoweza kukadiriwa ili kukidhi mahitaji ya ukubwa tofauti.

Ufungashaji

- Pipi za karanga zilizokamilika zafungwa kwa kutumia mashine ya kufungia vitafunwa ya moja kwa moja.

- Mifumo mbalimbali ya ufungaji inapatikana ili kuendana na uwezo tofauti wa uzalishaji na mitindo ya ufungaji.

- Mfumo wa ufungaji unahakikisha ushughulikiaji wa kiafya na kuboresha muonekano wa bidhaa kwa usambazaji wa soko.

Usanidi wa mashine & vigezo vya kiufundi

| Hakuna. | Jina la Mashine | Mfano | Data ya Kiufundi |

| 1 | Mchoma Karanga | TZM-1 | Nguvu ya Motor: 1.1 kW Nguvu ya Kupasha Joto: 23 kW Uwezo: 80–120 kg/h Ukubwa: 3000 x 1200 x 1700mm Aina ya Kupasha Joto: Kupasha kwa umeme Nyenzo: Chuma cha pua |

| 2 | Mashine ya Kumenya Karanga | — | Nguvu ya Motor: 0.55 kW Nguvu ya Fan: 0.75 kW Uwezo: 200–300 kg/h Voltage: 380V / 220V, 50 Hz Kiwango cha kusugua: ≥98% Ukubwa: 1100 × 400 × 1100 mm |

| 3 | Sufuria ya Kuyeyusha Sukari (Sufuria yenye koti) | TZ-200L | Nguvu: 18 kW Ukubwa: 950 × 950 × 800 mm Uzito: 120 kg Aina ya Kupasha Joto: Kupasha kwa umeme Muundo: Ina udelevu wa kuchanganya, inayoweza kuinuliwa Nyenzo: chuma cha pua 304 |

| 4 | Mashine ya Kuchanganya | — | Nguvu: 1.1 kW Voltage: 380V / 50 Hz Uwezo: 15 kg/batch Ukubwa: 700 × 500 × 1400 mm Muundo: Sufuria ya tabaka mbili na kuhifadhi joto |

| 5 | Mashine ya Kukata & Kuunda | TZ-68 | Nguvu: 2.5 kW Voltage: 380V / 50 Hz Uwezo: 300–400 kg/h Ukubwa: 6500 × 1000 × 1200 mm Uzito: 1000 kg Upana wa Mkanda: 560 mm |

| 6 | Mkataba wa Kupozesha | — | Nguvu: 0.37 kW Voltage: 380V / 220V Ukubwa: 5000 × 1000 × 800 mm Nyenzo ya mkanda: PVC Uso: Chuma cha pua |

| 7 | Mashine ya Kufunga | HY-250 | Nguvu: 1.92 kW Voltage: 220V / 50 Hz Upana wa Filamu Uliokuzwa: 250 mm Ukubwa: 3770 × 670 × 1450 mm Uzito: 800 kg Sifa: Imewekwa mfumo wa kusimbua tarehe |

Je, karanga brittle ni ngumu kutengeneza?

Kwa ukweli, ikiwa utatengeneza karanga ya kukandamizwa nyumbani, itakuwa ngumu kufanya. Kwa sababu inahitaji kukaanga karanga na kuchemsha sirapu. Lakini ikiwa utatumia laini ya uzalishaji ya vibandiko vya nafaka itakuwa rahisi sana kutengeneza.

Unahitaji tu kuandaa viambato kisha uendeshe programu ya laini ya uzalishaji wa vibandiko vya nafaka za karanga. Na uzalishaji wa viwandani ni safi zaidi na wa kiafya.

Karanga brittle dhidi ya praline

Hapa kuna kulinganisha kwa karanga ya kukandamizwa na praline. Kwa kutumia njia hii, laini yetu ya uzalishaji ya vibandiko vya nafaka yenye udhibiti wa moja kwa moja kabisa inaweza kutengeneza pipi za karanga na praline. Ikiwa una maswali yoyote, tafadhali jisikie huru kuwasiliana nasi wakati wowote.