Fully Automatic Cereal Bar Production Line | Peanut Brittle Making Machine

| Applicable Products | Peanut Brittle, Sesame Candy, Nut Bars, Cereal Bars, Energy Bars |

| Production Capacity | 300–400 kg/h |

| Power Supply | 220V / 380V, 50Hz |

| Heating Method | Electric heating (gas heating optional) |

| Bar Size | Adjustable, supports multiple shapes and sizes |

| Food-contact Material | 304 stainless steel |

| Automation Level | Fully automatic, only 1–2 operators required |

You can now ask our project managers for technical details

The 300-400kg/h fully automated cereal bar production line is specifically designed for large-scale manufacturing of nut candies, cereal bars, and healthy snack foods. The entire production process—from raw material mixing, heating and boiling, shaping and rolling, length-specific cutting, cooling, to final packaging—operates continuously. The workflow is tightly integrated, ensuring high efficiency and exceptional stability.

Equipped with an intelligent control system, the line allows precise adjustment of key process parameters to ensure consistent product texture and uniform appearance. Its flexible modular design accommodates diverse recipes and product forms, enabling rapid development of high-value-added innovations to enhance market competitiveness.

Applications of peanut candy production line

- Peanut and nut candy production: traditional and innovative confections including peanut brittle, sesame candy, nut candy, and chikki.

- Grain bars and energy foods: health foods such as oat bars, cereal bars, energy bars, protein bars, and meal replacement bars.

- Snack food processing enterprises: suitable for candy factories, snack food plants, and cereal food processing facilities.

- Startup and expansion projects: ideal for small-to-medium food enterprises or entrepreneurs entering the nut candy and cereal bar markets.

Features of peanut cereal bar production line

- Highly customizable: flexibly adjusts production line structure and equipment configuration based on product variety and capacity requirements.

- Food-grade safety standards: all material-contact components are constructed from 304 stainless steel, meeting food hygiene and safety requirements.

- High automation: continuous operation throughout the line ensures simple operation, requiring only one operator for production monitoring.

- Stable output and high efficiency: supports extended continuous production to fulfill large-scale order demands.

- Rapid market adaptability: quickly switch product types by adjusting recipes and molds, minimizing trial production costs.

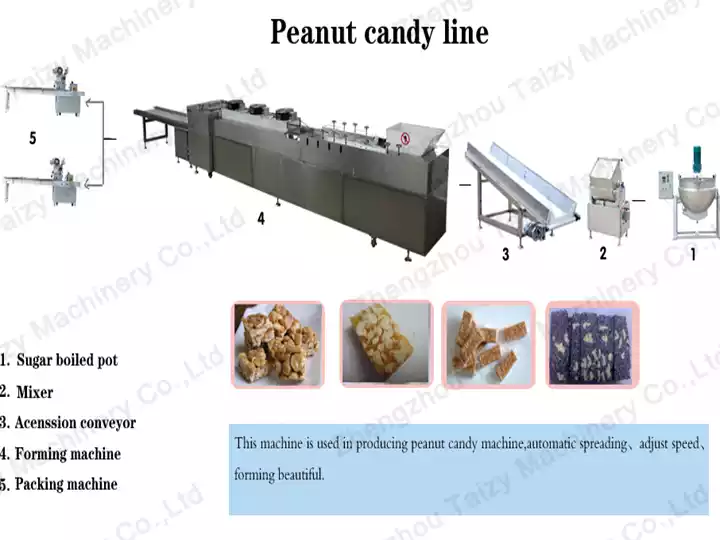

Complete peanut candy making process

The complete peanut cereal bar production line process involves baking, peeling, boiling sugar, mixing, briquetting, cooling, cutting, and packaging.

The whole cereal bar production line consists of a peanut roasting machine, a peanut peeling machine, a jacketed pan, a peanut candy forming and cutting machine, and a peanut candy packing machine.

How to make peanut brittle?

Roasting

- Peanuts are first roasted to enhance aroma and improve texture, which is essential for high-quality peanut candy.

- A commercial peanut roasting machine ensures even heating through continuous drum rotation, preventing local scorching.

- The roaster supports both electric and gas heating options and is suitable for peanuts, sesame seeds, walnuts, almonds, and other nuts.

Peeling

- After roasting, peanuts are peeled to remove the red skin, which can cause bitterness if left on.

- The peanut peeling machine uses roller friction for efficient skin removal.

- Peeling efficiency reaches up to 98%, with a low breakage rate to maintain kernel integrity.

Making syrup

- Sugar is melted into syrup using a jacketed kettle, forming the binding base of peanut candy.

- The built-in stirring system prevents sticking and ensures uniform heating.

- Additional ingredients such as honey can be added during this process to enhance flavor.

Mixing

- Roasted peanuts and syrup are thoroughly mixed to achieve uniform coating.

- The tilting mixer allows easy unloading and smooth operation.

- A food-grade inner lining prevents material from sticking to the mixing drum while maintaining low noise levels.

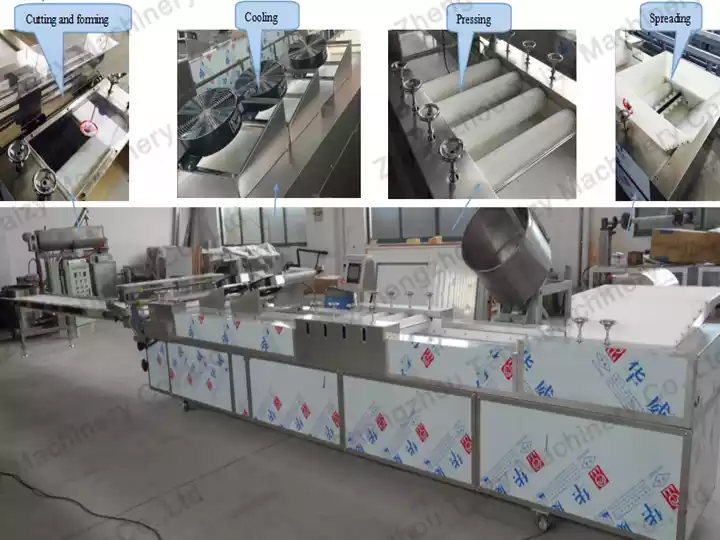

Forming and cutting

- The mixed material is fed into the peanut brittle forming and cutting machine, the core unit of the production line.

- A compression system shapes the mixture into flat slabs with consistent thickness.

- An air-cooling system helps stabilize the shape before cutting.

- The cutting unit slices the slabs into uniform bars or blocks, with adjustable speed to meet different size requirements.

Packing

- Finished peanut candies are packaged using an automatic snack packing machine.

- Multiple packaging models are available to match different production capacities and packaging styles.

- The packaging system ensures hygienic handling and improves product presentation for market distribution.

Machine configuration & technical parameters

| No. | Machine Name | Model | Technical Data |

| 1 | Peanut Roaster | TZM-1 | Motor Power: 1.1 kW Heating Power: 23 kW Capacity: 80–120 kg/h Size: 3000 x 1200 x 1700mm Heating Type: Electric heating Material: Stainless steel |

| 2 | Peanut Peeling Machine | — | Motor Power: 0.55 kW Fan Power: 0.75 kW Capacity: 200–300 kg/h Voltage: 380V / 220V, 50 Hz Peeling Rate: ≥98% Size: 1100 × 400 × 1100 mm |

| 3 | Sugar Boiling Pot (Jacketed Kettle) | TZ-200L | Power: 18 kW Size: 950 × 950 × 800 mm Weight: 120 kg Heating Type: Electric heating Structure: With stirring, tiltable Material: 304 stainless steel |

| 4 | Mixing Machine | — | Power: 1.1 kW Voltage: 380V / 50 Hz Capacity: 15 kg/batch Size: 700 × 500 × 1400 mm Structure: Double-layer pot with heat preservation |

| 5 | Cutting & Forming Machine | TZ-68 | Power: 2.5 kW Voltage: 380V / 50 Hz Capacity: 300–400 kg/h Size: 6500 × 1000 × 1200 mm Weight: 1000 kg Belt Width: 560 mm |

| 6 | Cooling Conveyor | — | Power: 0.37 kW Voltage: 380V / 220V Size: 5000 × 1000 × 800 mm Belt Material: PVC Surface: Stainless steel |

| 7 | Packing Machine | HY-250 | Power: 1.92 kW Voltage: 220V / 50 Hz Max Film Width: 250 mm Size: 3770 × 670 × 1450 mm Weight: 800 kg Feature: With a date coding system |

Is peanut brittle hard to make?

To be honest, if you make peanut brittle at home, it will be difficult to do. Because it requires both roasting peanuts and boiling syrup. But if you use the peanut cereal bar production line will be very good to do.

You only need to prepare the ingredients and then operate the peanut brittle cereal bar production line application. And industrial production is cleaner and more hygienic.

Peanut brittle vs praline

Here is the comparison of peanut brittle and praline. By the way, our fully automatic cereal bar production line can make both peanut candy and praline. If you have any questions, please feel free to contact us at any time.