Semi-Automatic Peanut Brittle Forming and Cutting Machine

| Modell | TZ-300 |

| Kapazität | 300-400kg/h |

| Breite Erdnusskrokant | Einstellbar |

| Breite der Presswalze | 560mm |

| Gesamtlänge | 11800mm |

| Länge des Förderbands | 5m |

| Anzahl der Presswalzen | 5 (0,75 kW) |

| Material | 201 Edelstahl |

| Sekundärschneidegerät | 220 V, 250 W |

Sie können jetzt unsere Projektmanager nach technischen Details fragen

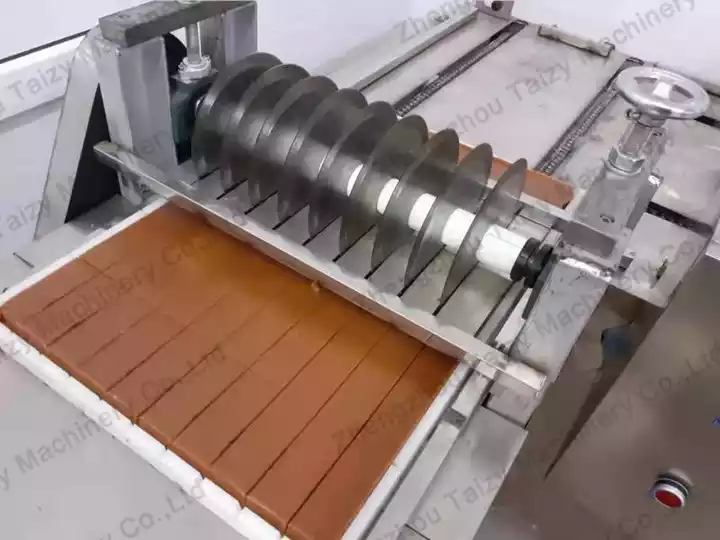

The peanut brittle forming and cutting machine serves as the core equipment for manufacturing peanut candy, peanut brittle, sesame candy, and various grain bars. Integrating block forming and cutting functions, it is suitable for small to medium-sized food processing plants and artisanal workshops.

Featuring a semi-automatic design, this line ensures uniform product appearance and consistent dimensions while significantly reducing manual labor intensity. Its compact structure and flexible operation deliver an output of 50–300 kg/h, meeting customers’ practical production needsacross different scales.

Equipment composition and application scope

This semi-automatic peanut brittle forming and cutting machine primarily consists of the following two components:

- Peanut Candy Block Forming Machine (Reciprocating Single-Roll Press)

- Cross-Cutting Machine with Automatic Discharge

The complete equipment is widely applicable for:

Forming and cutting various foods, including peanut candy, peanut brittle, sesame candy, sacha biscuit, rice puff candy, grain energy bars, sunflower seed candy, puffed grain candy, etc.

Peanut brittle forming and cutting machine features

- Effectively controls equipment investment costs, suitable for small to medium-scale production.

- Key contact components utilize food-grade SUS304/201 stainless steel, offering corrosion resistance and easy cleaning.

- Block thickness, width, and cutting dimensions are adjustable to meet diverse product specifications based on customer requirements.

- High-quality alloy blades and anti-adhesion pressure rollers minimize sticking and extend service life.

- Manual control with mechanical assistance ensures low failure rates. Compact footprint facilitates flexible workshop layout.

Peanut cereal bar forming machine working principle

The semi-automatic peanut brittle forming and cutting machine primarily consists of a compaction system, cooling system, and cutting system, featuring a clear and efficient overall process.

- First, the pre-mixed syrup and peanuts (or other ingredients) are manually fed into the block forming machine. The equipment compacts and shapes the material using reciprocating rollers, forming candy blocks of uniform thickness.

- Subsequently, the sugar blocks gradually set during conveying and natural cooling before entering the cutting zone. The cutter employs intermittent feeding, utilizing single or cross blades to rapidly slice the blocks into finished products of specified dimensions.

By adjusting mold and blade parameters, the production of peanut candy in various sizes and shapes can be flexibly achieved.

Parameters of peanut candy making machines

Peanut brittle flattening & forming machine

| Artikel | Specification |

| Stromspannung | 380V |

| Leistung | 1.5 KW |

| Kapazität | 150–300 KG/H |

| Abmessungen | 1600 × 800 × 1300 mm |

| Anwendung | Peanut brittle / candy forming |

| Discharge Type | Automatic discharge |

| Customization | No |

Peanut brittle cutting machine

| Artikel | Specification |

| Modell | QY-QKJ |

| Stromspannung | 380V / 220V |

| Leistung | 2 × 1.5 KW |

| Kapazität | 50–100 KG/H |

| Abmessungen | 1810 × 1680 × 1120 mm |

| Net Weight | 380 KG |

| Anwendung | Food cutting |

| Discharge Type | Conveyor top discharge |

| Customization | Yes |

Wie wird Erdnusskrokant hergestellt?

Peanut brittle is produced through a complete processing line rather than a single machine. In addition to the peanut brittle forming and cutting machine, the production process also includes a peanut roasting machine, peanut peeling machine, jacketed kettle, peanut candy mixer, and packaging machine.

- First, raw peanuts are roasted and peeled, while syrup is boiled in the jacketed kettle.

- The peeled peanuts are then poured into the syrup and thoroughly mixed.

- Next, the peanut-and-syrup mixture is transferred to the peanut candy forming and cutting machine for flattening, shaping, and cutting.

- After cooling, the finished peanut brittle can be packaged and prepared for sale.

For customers with higher capacity requirements and reduced labor needs, a fully automatic peanut brittle production line is also available, offering continuous production and higher efficiency.

Kontaktieren Sie uns

Do you need a peanut brittle forming and cutting machine, a cereal bar forming machine, or a cereal bar line? If you are interested, please feel free to contact us, and we will reply to you as soon as possible.