Peanut Peeling and Splitting Machine | Peanut Half Cutting Machine

| Model | Large Peanut Half Separating Machine |

| Capacity | 1000 kg/h |

| Main Power | 2.2 KW |

| Fan Power | 2.2 KW |

| Voltage | 380 V |

| Frequency | 50 Hz |

| Dimensions | 1900 × 1150 × 1350 mm |

You can now ask our project managers for technical details

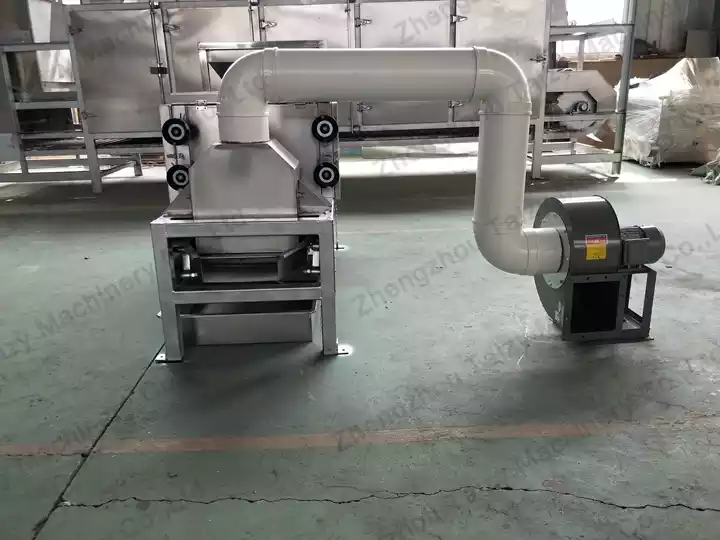

The peanut peeling and splitting machine integrates red skin removal with kernel separation, specifically designed for producing split peanuts. It achieves efficient shelling and uniform splitting while ensuring kernel integrity, delivering high splitting rates with minimal breakage, high halving rate above 96%.

The entire machine is equipped with a dust collection system and a vibrating screening structure, automatically separating skins and impurities. The finished peanut halves are clean, white, and visually appealing, with minimal material loss. It serves as an ideal pre-processing equipment for peanut deep processing and the food industry.

Specifications of peanut splitting machine

| Parameter | Large Model | Small Model |

| Capacity | 1000 kg/h | 400–500 kg/h |

| Main Power | 2.2 KW | 1.5 KW |

| Fan Power | 2.2 KW | 0.75 KW |

| Dimensions | 1900 × 1150 × 1350 mm | 1900 × 850 × 1350 mm |

| Voltage | 380 V | 380 V |

| Frequency | 50 Hz | 50 Hz |

Applications of peanut half cutting machine

The peanut peeling and splitting machine is primarily used in the deep processing of food and agricultural products, suitable for:

- Industrial processing of split peanuts.

- Raw material preparation for baked goods such as candies, cookies, cakes, and bread.

- Pre-processing of raw materials for peanut butter, canned peanuts, and snack foods.

- Peanut grading and deep processing for oil mills and food processing enterprises.

Beyond peanuts, this equipment can also be used for splitting certain legumes and coconuts, offering broad applicability. It is suitable for small-to-medium-sized and large-scale processing enterprises.

Peanut peeling and half separating machine features

- Integrated peeling and cutting: one machine completes two processes simultaneously, reducing production costs.

- High shelling efficiency: peanut shelling rate ≥96% with minimal breakage.

- Automatic deburring and impurity removal: vacuum system and vibrating screen effectively separate red skins and germ.

- Low noise, low energy consumption: smooth operation, energy-efficient, suitable for extended continuous operation.

- Superior product quality: peanut halves are uniformly white and aesthetically pleasing.

- Simple operation and maintenance: rational design ensures easy operation, cleaning, and upkeep.

- Eco-friendly and pollution-free: red skins are centrally collected, eliminating dust pollution.

How does peanut peeling and splitting machine work?

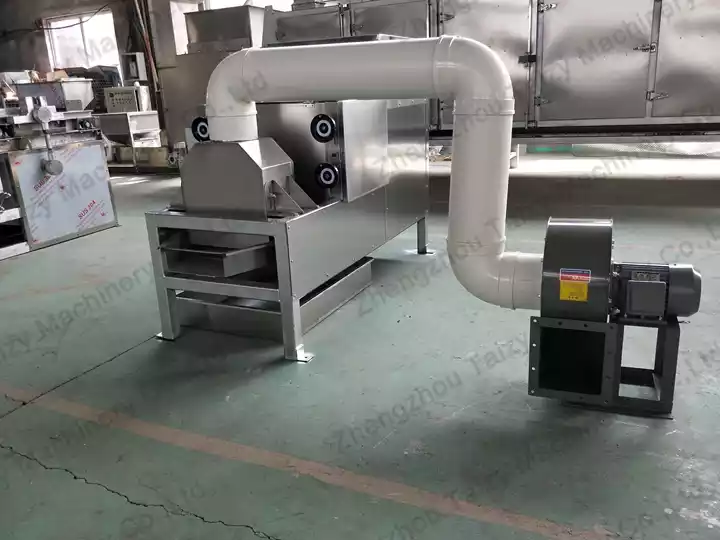

The peanut peeling and splitting machine achieves shelling and splitting through the coordinated operation of multiple structures:

- Roasted and cooled peanuts with their red skins enter a high-speed rotating shelling drum.

- Within the drum, friction removes the skins while simultaneously splitting the peanuts into halves.

- The separated peanuts are conveyed by a spiral feeder to a vibrating screen.

- Under the vibrating screen’s action, peanut skins and germ are effectively separated.

- A dust extraction fan concentrates and removes the skins, achieving clean, pollution-free automatic separation.

The entire process operates continuously and stably with high automation, ensuring a neat and clean appearance of the peanut halves.

We also offer dry-type peanut peeling machines and wet-type peanut skin removing machines for peanuts to meet your diverse production needs.

Thank you for visiting our website! Should you have any questions or feedback, please feel free to submit them via the form on the right. We will respond to your inquiry within 24 hours.