Delivery of Continuous Nut Roaster to the United States

The U.S. customer ordering this continuous nut roaster machine is based in California and represents a rapidly growing mid-sized food processing enterprise. The company has long specialized in the processing and sales of nut products, puffed grain snacks, and health-conscious snacks.

To further enhance product processing uniformity and quality consistency, the client decided to comprehensively upgrade its baking operations, prioritizing continuous processing, automation, energy efficiency, and food-grade hygiene standards.

Continuous nut roater machine selection

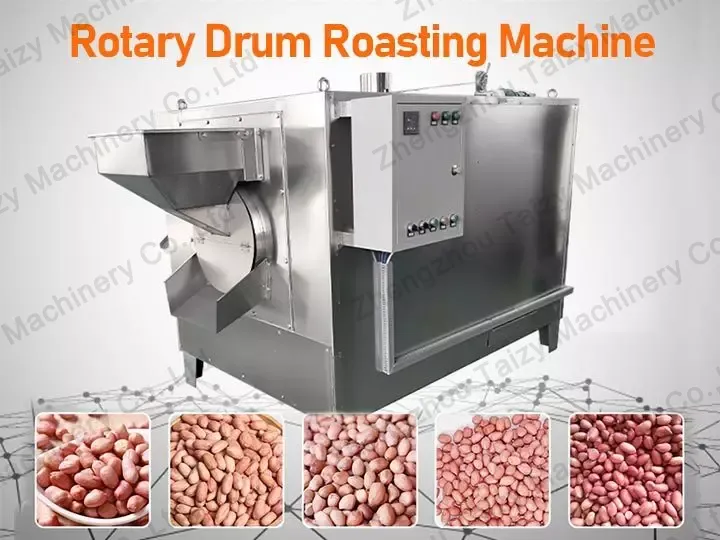

Based on the client’s production capacity requirements and product characteristics, we recommended an automatic continuous nut roaster. Constructed from food-grade stainless steel for robust durability, this equipment is specifically suited for continuous drying, roasting, and dehydration of nuts, grains, puffed foods, and similar materials. Key advantages include:

- Precise temperature control: multiple independent heating zones ensure uniform heat distribution throughout materials.

- Energy-efficient design: a recirculating hot-air system minimizes energy consumption while maximizing baking efficiency.

- High compatibility: seamless integration with the customer’s upstream and downstream conveying systems enables full automation of the production line.

- Exceptional stability: capable of 24/7 continuous operation, supporting high-intensity industrial production.

Customized roasting machine configuration

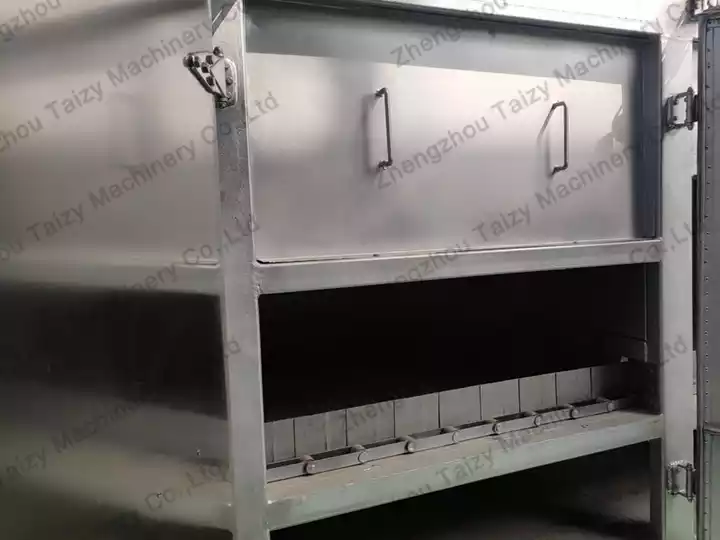

To ensure rapid deployment upon arrival, we tailored adjustments based on the customer’s existing workshop layout, including:

- Customized conveyor belt inlet height for seamless integration with the front-end feeding system.

- Optimized exhaust and airflow structures to meet the customer’s environmental and ventilation standards.

- Providing spare heating modules and high-temperature-resistant conveyor belts for future maintenance.

After manufacturing completion, the continuous nut roaster machine underwent comprehensive testing, including critical systems such as temperature control, conveying, and air circulation. Only upon passing all inspections did it proceed to packaging.

To ensure undamaged cross-border transit, we employ: multi-layered reinforced wooden crates, internal shock-absorbing mounting brackets, moisture-proofing, and rust-proofing treatments. The equipment has been successfully loaded and shipped to a U.S. port, with scheduled arrival at the customer’s facility.