4 Sets of Dry Peanut Peeling Machine Shipped to Pakistan

Great news! We have completed the production, testing, and loading of four dry peanut peeling machines, successfully shipping them to Pakistan. This customer has long been engaged in the processing and sale of fried peanut snacks. To enhance processing efficiency and ensure product quality, they selected our peanut shelling equipment.

Customer background and purchase requirements

This Pakistani client specializes in fried peanut snacks with stable market sales, demanding high-quality peeling results for raw peanuts.

Previously, manual peeling faced low efficiency and high breakage rates, compromising the appearance and texture of finished peanuts. To accelerate processing and reduce labor costs, the client decided to procure reliable peanut shelling machines.

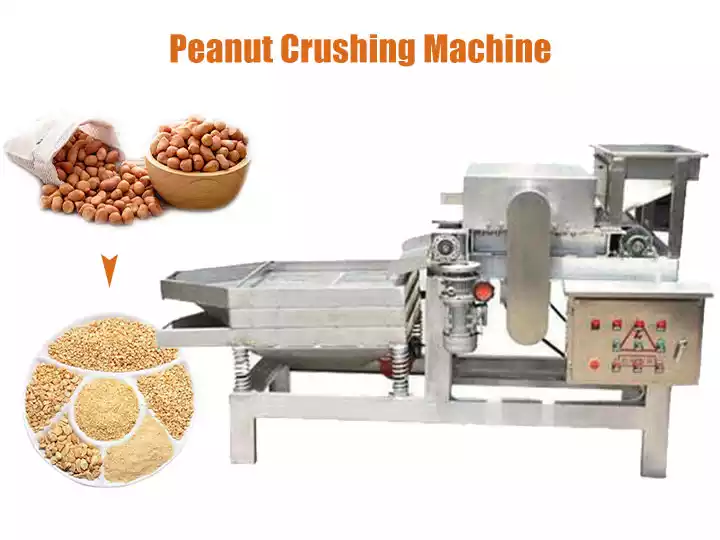

Product features of dry peanut peeling machine

The peanut shelling machine employs a dry shelling process. It is simple to operate and can quickly remove peanut skins with low breakage and high integrity rates. The finished peanuts have a smooth surface, suitable for subsequent frying, seasoning, and other processes.

- High peeling efficiency: achieves over 96% peeling rate, ensuring high-efficiency peanut processing.

- Low damage rate: maintains damage rate around 6%, guaranteeing intact finished product appearance.

- User-friendly operation: compact design facilitates easy installation and maintenance; requires minimal training for operators.

- Stainless steel construction: food-contact surfaces use stainless steel for hygiene and durability.

Before shipment, our technicians conducted comprehensive debugging and inspection of the four peanut peeling machines to ensure stable operation and performance compliance.

Workers then securely fastened the equipment and packaged it in fumigation-free wooden crates to enhance protection during transit. The loading process proceeded in an orderly manner, culminating in the successful shipment of the equipment, which has now departed for Pakistan.