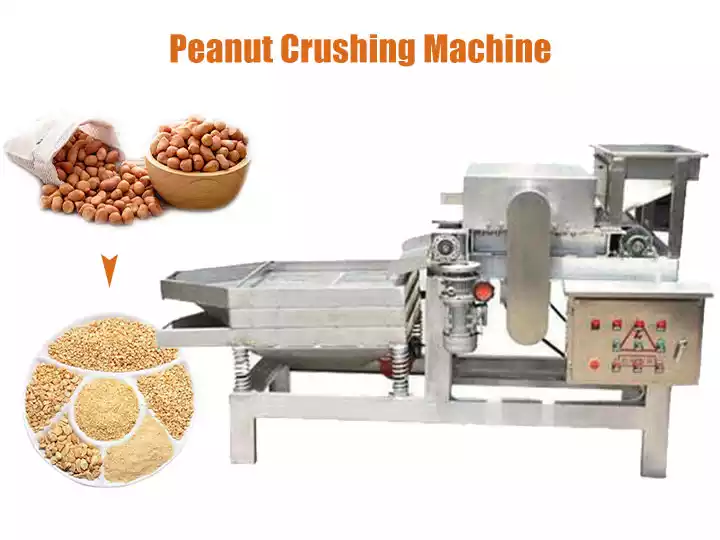

Peanut Crushing Machine | Nut Crusher Machine

| Model | TZ-600 |

| Capacity | 600kg/h |

| Voltage | 380v |

| Power | 4.9kw |

| Frequency | 50hz |

| Size | 1.8*0.8*2m |

| Weight | 600kg |

You can now ask our project managers for technical details

The peanut crushing machine is specifically designed for processing peanuts, almonds, and various other nuts. This equipment enables automatic crushing, grading, and screening of raw materials like peanuts, achieving a production capacity of up to 800 kg/h.

The machine features simple operation and high automation, saving labor while reducing energy consumption. It is an ideal choice for food processing plants and nut granulation production lines.

Utilizing precision blades and a vibrating screening system, the peanut granulator produces uniformly sized, consistent-grade finished granules. It supports customizable multi-stage screening according to customer requirements, ensuring precise cutting results for different particle sizes.

Application scope of peanut crusher machine

The peanut crushing machine is widely used in the food processing industry and can handle the following materials:

- Nuts: peanuts, almonds, walnuts, cashews, hazelnuts, chestnuts, etc.

- Seeds: pumpkin seeds, melon seeds, etc.

- Beans and other granular materials: such as soybeans, sesame seeds, and other cuttable granular or strip-shaped raw materials.

The equipment supports customer-customized crushing and screening devices for large granular materials, suitable for various production scales and granulation requirements.

Advantages of Taizy peanut chopping machine

- High-yield efficiency: automated crushing and screening system with output reaching 400-800 kg/h, ideal for large-scale production.

- Uniform granulation: vibrating screens and multi-stage blades ensure consistent particle size to meet diverse specification requirements.

- Automated operation: workers simply load peanuts into the hopper; the machine automatically completes pelletizing and grading.

- Food safety: entire unit constructed from 304 stainless steel food-grade materials, compliant with sanitary standards.

- Versatile & customizable: processes various nuts and granular materials, supports multi-stage custom screening configurations.

- Energy-efficient & eco-friendly: low-noise design, oil-free compression, stable operation, and easy maintenance.

How to crush peanuts?

The peanut crushing machine primarily consists of a feed hopper, conveying system, crushing system, and vibrating screening system:

- Feeding: peanuts or other nuts are evenly fed into the hopper and conveyed into the crushing zone via the conveying system.

- Granulation and crushing: multiple rotating blades crush the nuts, cutting them into the desired size.

- Screening and grading: the crushed material passes through the vibrating screening system, separating particles that meet specifications. Non-compliant particles are returned for re-cutting.

- Discharge: material meeting the standard particle size is automatically discharged through the outlet, enabling a continuous and efficient cutting process.

This system can be customized with different screen meshes and cutting stages according to customer requirements, achieving the desired particle size and production efficiency.

Nut crushing machine parameters

| Model | Capacity | Voltage | Power | Frequency | Size | Weight |

| TZ-400 | 400kg/h | 380v | 0.75*2kw | 50hz | 1.6*0.8*1.5m | 300kg |

| TZ-600 | 600kg/h | 380v | 4.9kw | 50hz | 1.8*0.8*2m | 600kg |

Please note: when purchasing a peanut crushing machine, carefully select the machine size to ensure it fits within the reserved space for the peanut crusher.

Double-roller almond chopping machine

In addition to the straight-blade pelletizer described above, we also offer a double-roll peanut pelletizer. This machine is equally suitable for customers with high requirements for pellet uniformity and product integrity.

The double-roll pelletizer employs a dual-roll compression-cutting structure. Material passes between two synchronously rotating pelletizing rolls, achieving pelletization through a combination of compression and shearing forces.

The entire cutting process is smooth and stable, resulting in minimal powder generation, low breakage rates, and uniform particle sizes. This effectively ensures consistent product appearance and quality.

This machine is particularly suitable for processing foods such as peanut brittle, cereal bars, nut brittle, and snack nuts. Granulating roll specifications can be customized according to customer requirements. Different roll types can achieve varying particle sizes, meeting diverse product formulations and process demands.

The following are the parameters of a regular roller-type peanut crushing machine:

- Model:TZ-1

- Power: 0.93kw

- Voltage: 380v 50hz three phase

- Capacity: 100-200kg/h

- Size: 1600*800*1500mm

If you have any other requirements regarding production volume or other specifications, please feel free to contact us.

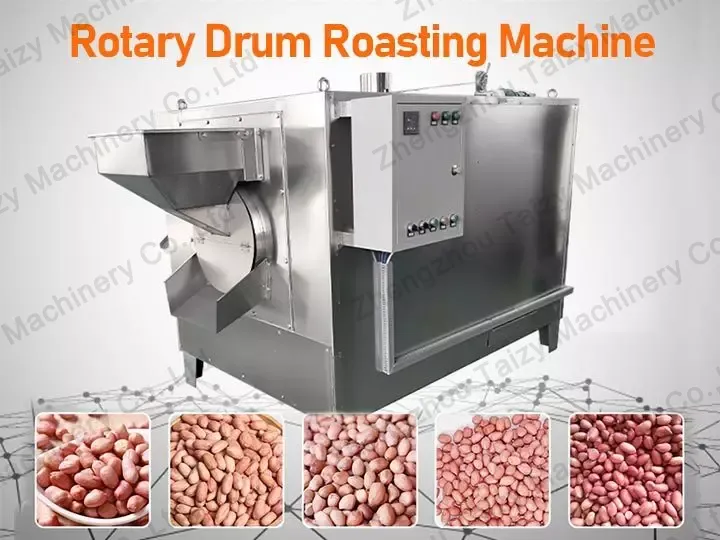

In addition, we also have the roasted peanuts machine and commercial peanut butter machine. If you need it, welcome to ask us.

FAQ

Can the particle size be adjusted? Is the finished product uniform?

Adjustable. The machine controls particle size by replacing screens and adjusting conveyor speed, supporting multi-stage screening to ensure consistent particle uniformity.

Is the equipment material safe? Is it easy to clean?

The entire unit uses food-grade 304 stainless steel—rust-resistant, easy to clean, and compliant with food processing hygiene standards. The blade design prevents oil extrusion.

How many operators are needed? Is it highly automated?

Only one worker is required for feeding. The machine automatically handles feeding, granulating, and screening, reducing labor costs.

Is the machine durable? Is maintenance troublesome?

The equipment features a simple structure and wear-resistant blades. Maintenance primarily involves cleaning and basic inspections. Wear parts are affordable, ensuring long-term stable operation.

Is the machine noisy during operation? Does it generate dust or pollution?

The peanut crushing machine features a low-noise design. The vibration screening system produces minimal dust, making it highly suitable for food processing environments.

Can the equipment be customized to my product requirements?

Yes. We can customize solutions for different output capacities, pellet specifications, multi-stage screening systems, and specialized nut crushing needs.

Is the machine power-hungry? Are electricity costs high?

The equipment features optimized power consumption and energy efficiency, resulting in lower long-term operating costs compared to traditional manual crushing methods.

What is the price? Do you provide installation or technical support?

Pricing is determined by production capacity configuration. We offer comprehensive technical support, including operation videos, remote guidance, and on-site engineer services upon request.