Flour Coated Peanut Production Line | Peanut Coating Processing Line

| Peanut roasting machine | 50-500kg/h |

| Peanut peeler machine | 200-1000kg/h |

| Peanut coating machine | 30-300kg/h |

| Frying machine | 500kg/h |

| Swing oven | 80-300kg/h |

| Flavoring machine | 300-1500kg/h |

| Cooling machine | 80-100kg/h |

| Packaging machine | 50-100 bag/min |

You can now ask our project managers for technical details

The coated peanut production line is specifically designed for the large-scale, fully automated processing of coated peanuts and other coated legume snacks. It uses peanuts, broad beans, cashews, macadamia nuts, and other ingredients as primary raw materials, undergoing processes such as roasting, shelling, coating, baking, seasoning, cooling, and packaging.

The final product features an even coating, an attractive appearance, and a crispy texture, making it highly popular in the market. It is ideal for investment and use by medium to large-scale food processing plants and snack food companies.

This coated peanut production line boasts a high degree of automation, typically requiring only 4 workers to operate the entire line. This not only effectively reduces labor costs and lowers production expenses but also significantly enhances production efficiency and product quality.

Application of peanut coating production line

- Peanut products: sugar-coated peanuts, powder-coated peanuts, honey peanuts, spicy peanuts, mustard peanuts, chocolate peanuts, peanut burgers, etc.

- Bean products: coated broad beans, coated green beans, coated peas, coated edamame, etc.

- Nut products: coated cashews, macadamia nuts, sunflower seeds, etc.

- Diversified snacks: can be expanded to include spicy crispy chips, puffed foods, chocolate beans, seafood-coated snacks, and other specialty snacks.

Advantages of peanut coating production line

- The process parameters of the entire coated peanut production line (temperature, speed, angle, etc.) can be freely adjusted to achieve continuous production with minimal manual supervision.

- The coating is uniform and consistent in thickness, resulting in a smooth and attractive surface finish, a crisp texture, and high repurchase rates.

- Customized production capacities can be tailored to meet the needs of both small-scale and large-scale processing operations.

- All parts in contact with food are made of food-grade stainless steel, which is durable, easy to clean, and compliant with food safety standards.

- Adjustable parameters include tilt angle, heating method, and speed, with optional accessories such as spray gun systems and dust collection systems.

- Suitable not only for peanuts but also for processing various legumes and nuts, meeting diverse market demands.

Main equipment of coated peanut production line

Peanut roasting machine

Peanut roaster is used to roast peanut kernels. The roller design can make the peanuts heated evenly and not easy to roast paste. And it can reduce the breakage rate of peanuts.

At the same time, the humidity of peanuts will be reduced to less than 5%. You can choose a variety of heating methods such as electric heating, gas heating, and coal heating.

| Model | Dimension (mm) | Capacity (kg/h) | Power (kw) | Electricity Heating (kw) | Gas Heating (kg) |

| TZ-1 | 3000*1200*1700 | 80-120 | 1.1 | 18 | 2-3 |

| TZ-2 | 3000*2200*1700 | 180-250 | 2.2 | 35 | 4-6 |

| TZ-3 | 3000*3300*1700 | 280-350 | 3.3 | 45 | 6-8 |

| TZ-4 | 3000*4400*1700 | 380-450 | 4.4 | 60 | 8-10 |

| TZ-5 | 3000*5500*1700 | 500-650 | 5.5 | 75 | 10-12 |

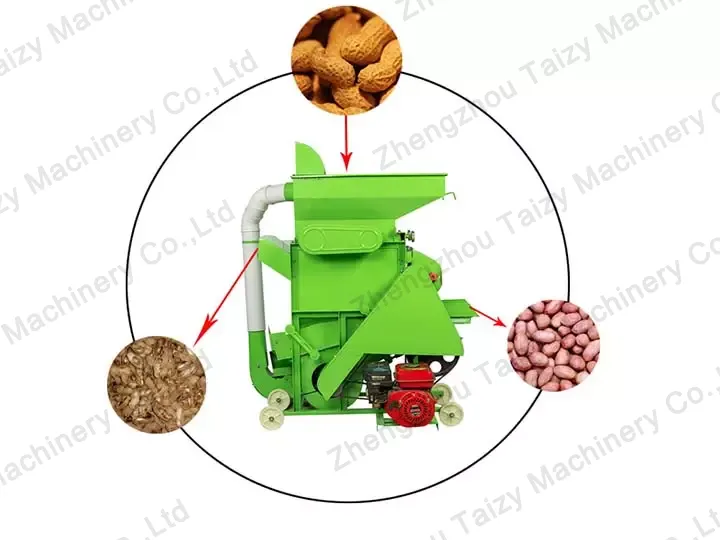

Peanut peeling machine

The dry peanut peeling machine can separate the peanut skin from the peanut kernel. The peeling rate of the machine is over 96%.

| Complete Rate | ≥96% |

| Dimension | 1100*400*1000mm |

| Capacity | 200-250kg/h |

Coated peanut making machine

The peanut coating machine is the main machine in the flour coated peanut production line. The coating machine is to make the material roll and rub inside the machine under the action of centrifugal force.

Then the peanut kernel is evenly mixed with powdered sugar, and the surface of the coated peanut made by our machine is smooth.

| Power | 1.1kw/380v, 220v |

| Weight | 180kg |

| Dimension | 1200*1000*1300 |

| Diameter | 1000mm |

Peanut swing oven

The peanut swing roaster is a machine that roasts the wrapped peanuts by means of electrical heating and gas heating. This machine is easy to operate. Workers just need to pour the peanuts into the peanut roaster. Then wait for 15 minutes to get out of the oven.

| Power | 25.75kw |

| Voltage | 380v/50hz |

| Size | 2200*2000*1500mm |

| Heating Power | 25kw |

| Swing Power | 0.75kw |

| Weight | 500kg |

| Speed | 40-60times/min |

Peanut seasoning machine

The peanut seasoning machine can mix the peanuts and seasoning well. Our machine can be connected with an external spraying device or manually pouring material. Users can add the required seasoning to the machine according to their needs.

| Power | 1.1kw/380v |

| Weight | 150kg |

| Dimension | 1000*800*1300mm |

| Barrel Diameter | 1000mm |

| Capacity | 300kg/h |

Peanut cooling machine

The peanut cooler is a machine used to reduce the temperature of the wrapped peanuts. This is to prepare for the subsequent packing. The machine mainly consists of the cooling part and storage part.

| Model | Capacity (kg/h) | Fan Power (kw) | Voltage/Frequency | Dimension (mm) |

| TP-1 | 200-300 | 1.1 | 380V/220v 50HZ | 1300*600*600 |

Peanut granule packing machine

The peanut granule packing machine is suitable for packing peanut granules, popcorn, various nuts, and other granular materials. It is also the last machine in the coated peanut production line.

| Bag Style | Back Seal (customizable) |

| Packing Speed | 37-72 bag/min or 50-100bag/min |

| Bag Length | 30-180mm |

| Filling Range | 22-220ml |

| Power Consumption | 1.8kw |

| Weight | 250kg |

| Dimensions | 650*1050*1950mm |

| Carton Size | 1100*750*1820mm |

Summary

The sugar coated peanut production line needs to be customized according to the specific customer’s output and production plant size. As a trusted supplier of peanut processing machinery. Our company provides a series of customized services such as perfect process flow and equipment customization.

If you are seeking efficient, safe, and customizable coated peanut production line equipment, please do not hesitate to contact us for detailed specifications and customized solutions.