Successful Case of Groundnut Harvester Machine Shipped to Guyana

Our factory completed and shipped a groundnut harvester machine to Guyana, a South American country. The buyer is a local company specializing in peanut cultivation and peanut butter production. In order to improve the harvesting efficiency and shorten the harvesting period, the customer decided to purchase a peanut harvesting machine.

Customer background and industry needs

The client has a 200 hectare plantation and a modern peanut butter production line. Its business has the following limitations:

- Insufficient harvesting efficiency: traditional manual harvesting requires 15 man-days to complete 1 hectare, with a 20% loss rate during the harvesting season.

- Processing quality limitations: manual harvesting causes soil mixing and pod breakage, leading to the risk of impurities in the sauce exceeding the standard.

- High labor costs: harvesting accounts for a high percentage of total production costs, severely restricting production expansion plans.

Core parameters of groundnut harvester machine

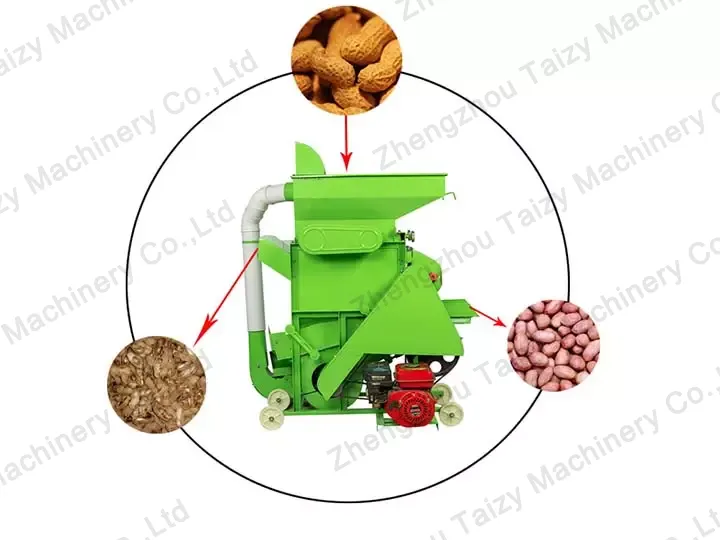

The equipment can complete digging, separating, shaking and spreading in one go, reducing the rate of peanut loss, which is particularly suitable for Guyana’s climatic conditions and soil types.

| Module | Technical program | Core value |

| Power adaptation | 20-35HP tractor PTO drive | Matches the mainstream agricultural models in Guyana |

| Harvesting system | Double-action toothed rollers + vibrating sieve chain | Soil separation rate ≥95 |

| Operating efficiency | 1300-2000 square meters/hour | Equivalent to 15 people working at the same time |

| Lightweight design | Aerospace aluminum frame (total weight 280kg) | Reduces soil compaction |

Preparation for shipment

After the completion of the peanut harvester machine, our technical team on the equipment for many rounds of debugging and field trials, to ensure that the equipment can be used directly.

At the same time, according to customer demand supporting shipment of technical information and operation manuals, convenient for customers to quickly start using.

At the shipping site, the equipment is firmly packed to prevent collision damage during transportation, and with the export shipping standards to implement the shipping process to ensure that the equipment arrives safely at the port of Guyana.