Continuous Peanut Roasting Oven | Multifunctional Nuts Roaster

| Model | TZ-500 |

| Capacity | 500kg/h |

| Size | Hoist: 2.5*0.7*2.8m Roasting oven: 8.5*1.8*2.6m |

| Heating power | 130kw |

| Power | 15kw |

You can now ask our project managers for technical details

The belt-type continuous peanut roasting oven is a multifunctional device that combines low-temperature drying and high-temperature roasting functions, suitable for the continuous processing of various nuts and granular materials.

The equipment supports electric heating or gas heating and is equipped with a hot air circulation system, which can effectively save energy and reduce consumption. It is widely used in food processing enterprises for the automated roasting of agricultural products such as peanuts, sesame seeds, and sunflower seeds.

By adjusting the temperature and conveyor belt speed, the machine can flexibly achieve continuous automatic roasting throughout the entire process from raw material feeding to product discharge, making it an ideal device for improving production efficiency and product quality.

Highlights of continuous automatic roaster

- Flexible temperature control: wide temperature range (0-300°C adjustable) to meet various needs from low-temperature drying to high-temperature baking.

- User-friendly operation: fully automatic operation design requires only one operator, saving labor costs.

- Food-grade materials: all parts in contact with materials are made of stainless steel, ensuring safety, hygiene, and easy cleaning.

- Energy-efficient and environmentally friendly: high-quality insulation material and hot air circulation system significantly reduce heat loss.

- Even baking: a rational hot air distribution structure ensures uniform heating of materials, resulting in better color and flavor.

- Automatic cooling system: prevents over-baking and improves product stability.

- High adaptability: adjustable conveying speed (25-40 Hz) and material thickness (4-10 mm) to flexibly accommodate different material requirements.

Conveyor roasting oven application scope

This continuous peanut roasting oven is suitable for roasting a variety of nuts and agricultural by-products, including but not limited to:

- Various types of peanuts (shelled/unshelled).

- Sesame seeds, sunflower seeds (sunflower seeds, pumpkin seeds, etc.).

- Soybeans, green beans, broad beans, peas, and other legumes.

- Cashews, almonds, walnuts, pine nuts, hazelnuts, pistachios, and other nuts.

- Dried chili peppers, dried fruits, dried vegetables, and other flavored foods.

Whether for drying, roasting, or enhancing aroma, this machine can precisely meet the processing requirements of different products.

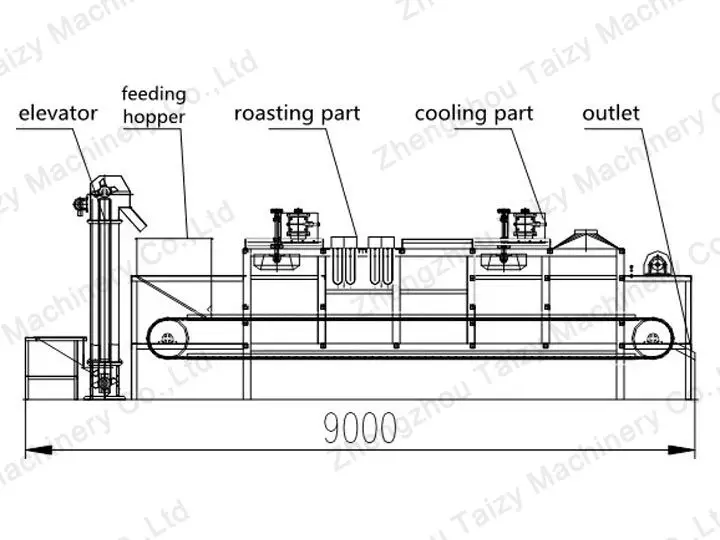

Structure of continuous peanut roasting oven

The continuous peanut roasting oven includes an elevator, a feeding section, a roasting section, a cooling section, a discharging section, and a vibrating screen section. Various areas are insulated to reduce heat loss and lower operating costs.

Nut roasting machine working principle

You can use either electricity or gas to roast peanuts.

- First, the operator should load the peanuts into the feed hopper. Then, an elevator will move the peanuts to the roasting system.

- After that, the peanuts will be evenly distributed on the roasting chain plate. The baking oven can reach temperatures of 180-200℃. After about 20 minutes of roasting, the peanuts will be done.

- They will then move to the cooling section of the continuous peanut roasting oven. After 10 minutes, the cooled peanuts will be released from the discharge port.

Details of the work process

- By utilizing separate burners for both top and bottom heating, the furnace is easier to control and more responsive.

- Each zone has its own temperature settings, allowing for independent control.

- To minimize energy use, one burner is designated for top heating and another for bottom heating in each zone.

- Unlike conventional ovens that stop working if a burner fails, our ovens continue to function effectively due to the presence of multiple burners, ensuring reliability.

- After the baking process, a final cooling section is included to prevent the product from exiting the oven too hot and absorbing moisture from the air.

- Additionally, a feed shaker can be installed at the input end and a collection shaker at the output end upon request.

Almond roasting machine parameters

| Type | TZ-200 | TZ-300 | TZ-500 | TZ-1000 |

| Capacity (kg/h) | 200 | 300-350 | 500 | 1000 |

| Size (m) | Hoist: 1.5*0.8*2.8 Roasting oven: 6.9*1.5*2.6 | Hoist: 1.5*0.8*2.8 Roasting oven: 7.5*1.5*2.6 | Hoist: 2.5*0.7*2.8 Roasting oven: 8.5*1.8*2.6 | Hoist: 2.5*0.7*2.8 Roasting oven: 11*2.1*2.6 |

| Heating power (kw) | 46 | 70 | 130 | 230 |

| Power (kw) | 10 | 10 | 15 | 15 |

Roasting improves the quality of peanuts and can yield different results, allowing for various types of production, including peanut blanching, chopping, coating, grinding for peanut butter production lines, and frying.

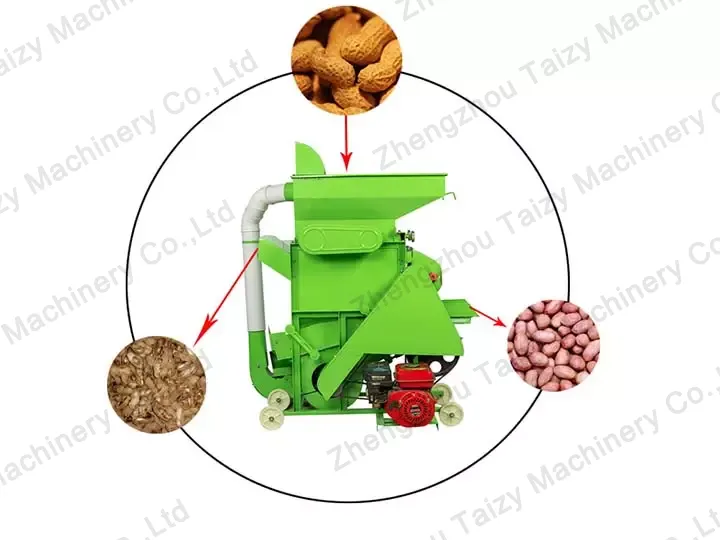

Moreover, we have another type of peanut roasting machine for sale. The pictures and videos of the machine are shown below:

If you need efficient roasting equipment for your nut processing line, our machines are undoubtedly a reliable choice. If you have special requirements, please contact us and we will provide customized options.