Groundnut Oil Extractor | Screw Peanut Oil Expeller

| Model | TZ-80 |

| Press Diameter | 80mm |

| Press Speed | 35r/min |

| Motor | 4kw |

| Vacuum Pump | 0.55kw |

| Heating Power | 2.2kw |

| Capacity | 80-120kg/h |

| Weight | 850kg |

| Size | 1.7*0.11*1.6m |

You can now ask our project managers for technical details

The automatic screw groundnut oil extractor is designed for peanut, soybean, rapeseed, sunflower seed and other oil crops with oil yield less than 40%. Compared with the traditional oil extraction method, the machine improves the oil yield efficiency by 35%-50% and reduces the energy consumption by 60%.

It is compatible with more than 20 kinds of oilseeds at the same time, and guarantees the purity of oil with a food-grade stainless steel process. With its compact structure and easy operation, it can be widely used in family workshops, small oil mills, and oil processing projects at the early stage of business.

Peanuts screw oil extraction machine advantages

- Small footprint: only 10-20 square meters, suitable for various sites.

- High-efficiency pressing system: optimized design of the pressing chamber enhances the internal pressure and greatly improves the oil pressing efficiency.

- Wide range of applicable raw materials: more than 20 kinds of oil raw materials can be processed to meet diversified production needs.

- Strong processing capacity: it can process 500 kilograms of raw materials per hour, and it is easy to operate, only one person can complete the production.

- Sturdy and durable structure: the whole groundnut oil extractor is made of high-quality carbon steel, wear-resistant and durable, supporting long-term continuous operation.

- High oil yield: the oil yield can reach about 50%, the residual oil rate of dry cake is less than 8%, and the oil utilization rate is high.

Application range of screw oil press machine

This groundnut oil extractor machine is suitable for a wide range of vegetable oilseeds and nuts raw materials, including but not limited to: mustard seed, sunflower seed, rapeseed, soybean, castor seed, shea nut, coconut or copra seed, neem seed, cottonseed, jatropha seed, corn germ, flaxseed, palm kernel, peanut, sesame seed, and so on.

If you are not sure whether your raw materials are suitable, please feel free to contact us. We can provide you with a free raw material testing service to help you evaluate the oil production effect.

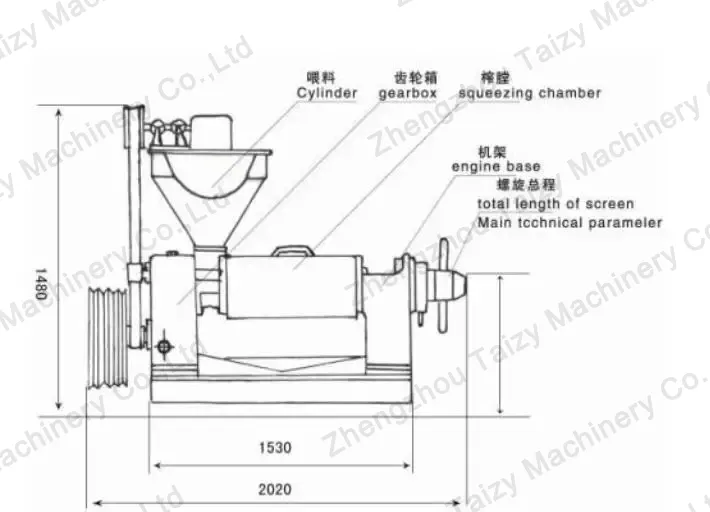

Screw oil extractor structure and working principle

The groundnut oil extractor mainly consists of automatic control box, heating and pressing part, adjusting device, rotating part and vacuum filtration system. All the parts work together to realize the fully automatic and efficient oil pressing process from raw material feeding, heating, and pressing to grease filtering.

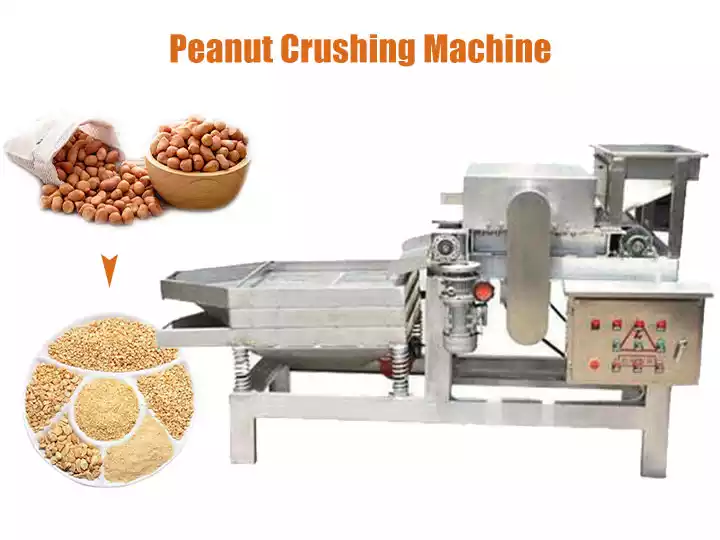

- Raw material pretreatment: according to the oil content and physical properties of the oilseeds, usually need to go through cleaning, drying, crushing, rolling embryo, steaming and tempering and other pretreatment steps.

- Feeding: the pre-treated peanut kernel and other raw materials are poured into the hopper.

- Screw propulsion and pressurization: driven by the screw shaft, the material moves forward; as the space in the pressing chamber gradually shrinks, the density of the material increases, and the internal pressure rises.

- Oil and grease precipitation: under the effect of high temperature and pressure and friction heat, the cell structure of the oil material is destroyed and the oil and grease are released.

- Vacuum filtration: the extracted oil passes through the vacuum filtration system to remove the dregs and impurities and get the pure edible oil.

- Finished product collection: the filtered edible oil can be collected and used.

Parameters of groundnut oil extractor machine

| Model | TZ-60 | TZ-70 | TZ-80 | TZ-180 | TZ-125 |

| Press Diameter | 55mm | 65mm | 80mm | 100mm | 125mm |

| Press Speed | 64r/min | 38r/min | 35r/min | 37r/min | 34r/min |

| Motor | 202kw | 3kw | 4kw | 7.5kw | 15kw |

| Vacuum Pump | 0.75kw | 0.75kw | 0.55kw | 0.75kw | 0.75kw |

| Heating Power | 0.5kw | 1.1kw | 2.2kw | 3kw | 3.75kw |

| Capacity | 40-60kg/h | 50-70kg/h | 80-120kg/h | 150-230kg/h | 300-350kg/h |

| Weight | 240kg | 280kg | 850kg | 1100kg | 1400kg |

| Size | 1.2*0.48*1.1m | 1.4*0.5*1.2m | 1.7*0.11*1.6m | 1.9*1.2*1.3m | 2.6*1.3*2.3m |

Which groundnut is best for oil extraction?

- Consider the size of the peanut kernel. If the peanut kernel is too large, it won’t fit through the feed opening of smaller oil press machines. Conversely, if the kernel is too small, the downstream speed will be too high, which can hinder oil yield. .

- Check if the peanut kernel is fresh. It’s essential that the peanuts used for oil extraction are not moldy, as moldy kernels contain aflatoxin, a potent carcinogen.

- Examine the variety of peanut kernels. There are several types of peanuts, including ordinary peanuts, pearl peanuts, multi-grain peanuts, and dragon peanuts. The ordinary type is the most suitable for oil extraction, boasting an oil content of 52-54%.

How to start groundnut oil extraction business?

- Conduct a thorough market analysis. It’s essential to determine if peanuts are cultivated in the area, assess the quality of the peanuts, understand the local demand for peanut oil, and evaluate the income levels of the population.

- Select an appropriate location to set up a peanut oil extraction business. After that, obtain the necessary business license from the relevant government department.

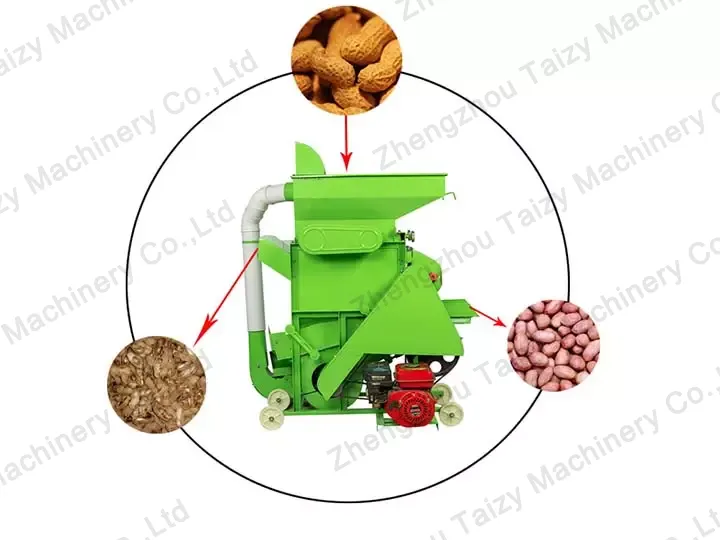

- Buy groundnut oil processing machine equipment. If you want to start a peanut oil press factory, then a peanut oil press is not enough. You need a peanut shelling machine, peanut peeling machine, groundnut oil extractor, peanut filling machine, and other related equipment

- Market your peanut oil. Finally, you need to find sales channels to sell your peanut oil.

We welcome inquiries in English, French, Arabic, Spanish, Russian, and many other languages. Our professional team will respond to you within one business day. If you are interested in our groundnut oil extractor machine, don’t hesitate to reach out to us!