Peanut Grading Machine | Nut Grading Sorting Machine

| Screening Level | 4 |

| Dimensions (LxWxH) | 2.4 × 0.8 × 1.9 m |

| Capacity | 600–800 kg/h |

| Weight | 300 kg |

| Power | 1.5 kW |

| Voltage | 380 V |

| Frequency | 50 Hz |

You can now ask our project managers for technical details

The peanut grading machine is primarily used for precise grading of materials such as apricot kernels, peanut kernels, almonds, hazelnuts, macadamia nuts, and soybeans into different specifications. They can sort materials into 3–5 grades at once based on size, facilitating subsequent storage, packaging, and graded sales.

The entire machine consists of a multi-layer vibrating screen body, commonly configured with three or four screening layers. Screen aperture sizes typically range from 6–10 mm, allowing flexible replacement of screen plates to suit different materials, ensuring strong adaptability.

Constructed entirely from carbon steel, this peanut grading machine maintains low breakage rates and high grading accuracy during continuous operation. A rational screen inclination angle and return material structure ensure thorough screening on each layer before progression to the next, effectively preventing grading confusion.

What materials can the machine process?

- Nut processing industry: grading of peanut kernels, almonds, hazelnuts, cashews, pistachios, macadamia nuts, etc.

- Legume sorting: size grading of agricultural products like soybeans, mung beans, and red beans.

- Agricultural primary processing: used for raw material pretreatment to enhance product standardization.

- Nut trading & packaging enterprises: provides stable front-end screening support for graded pricing and specification packaging.

Advantages of peanut grading machine

- Strong multi-level sorting capability: achieves 3–5 levels of screening, with customizable layer counts per client requirements.

- High sorting precision: return plate design prevents unsorted material from falling directly to lower layers.

- Stable and reliable operation: sprocket and chain-driven pusher mechanism ensures smooth, consistent reciprocating motion of the screening body.

- Resistant to clogging: optimal vibration frequency and screen aperture design maintain unobstructed flow even at high throughput.

- Simple operation: high automation requires only material feeding for continuous grading.

- Wide applicability: a single unit processes multiple nuts and legumes, maximizing equipment utilization.

Nut grader machine working principle

- The peanut grading machine screen employs a sprocket and chain-driven push rod mechanism to induce rhythmic reciprocating vibration across multiple screening layers.

- After entering the screening system through the feed inlet, materials advance across the screen surface under vibration.

- Materials of different sizes sequentially pass through corresponding screen layers based on aperture size. Each layer incorporates a return plate beneath it, ensuring thorough screening on the surface before progression to subsequent stages.

- Finally, nuts or beans of distinct specifications are discharged separately through corresponding outlets, achieving precise and efficient grading operations.

Technical data of nut classifier machine

| Screening Level | Dimensions (LxWxH) | Capacity | Weight | Power | Voltage | Frequency |

| Single-Level Screen | 1.6 × 0.8 × 0.6 m | 150 kg/h | 260 kg | 0.18 kW | 380 V | 50 Hz |

| Two-Level Screen | 2.4 × 0.8 × 1.4 m | 200 kg/h | 260 kg | 1.1 kW | 380 V | 50 Hz |

| Three-Level Screen | 2.4 × 0.8 × 1.6 m | 600–800 kg/h | 300 kg | 1.1 kW | 380 V | 50 Hz |

| Four-Level Screen | 2.4 × 0.8 × 1.9 m | 600–800 kg/h | 300 kg | 1.5 kW | 380 V | 50 Hz |

| Five-Level Screen | 2.4 × 0.8 × 2.2 m | 500 kg/h | 500 kg | 1.5 kW | 380 V | 50 Hz |

FAQ

How many grades can the peanut grading machine sort into at most?

It can be configured for 1–5 grades of screening based on requirements, with 3 or 4 grades being commonly used.

Can the screen aperture size be changed or customized?

Yes. Screen plate apertures can be customized for different nut varieties and grading standards, and are easy to replace.

Will the nuts be crushed during screening?

No. The peanut grading machine employs a rational vibration method and structural design, resulting in low breakage rates.

Does the equipment clog screen apertures during operation?

Clogging is unlikely. The screen body vibrates stably and features a return plate structure to ensure thorough screening.

What power configuration does the equipment require?

The standard configuration is 380V, 50Hz, which can be adjusted according to customer requirements.

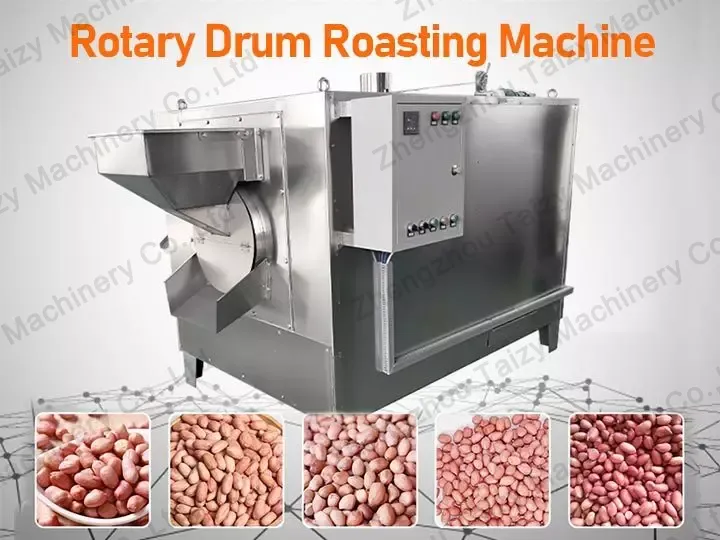

As a peanut processing machinery supplier with rich production experience, we also have the roasted peanuts machine, commercial peanut butter machine, and other machines.

Feel free to contact us anytime for detailed specifications, configuration options, and pricing information to obtain a professional solution tailored to your production needs.