Enhance Your Production with a Peanut Coating Machine

In the realm of food processing, the efficiency and quality of peanut coating machines play a pivotal role in optimizing production processes. These machines are designed to apply coatings evenly to peanuts, ensuring a consistent and appealing final product. If you’re seeking information on “how much is a peanut coating machine,” understanding their features, benefits, and cost factors becomes essential to making an informed investment.

What Is a Peanut Coating Machine?

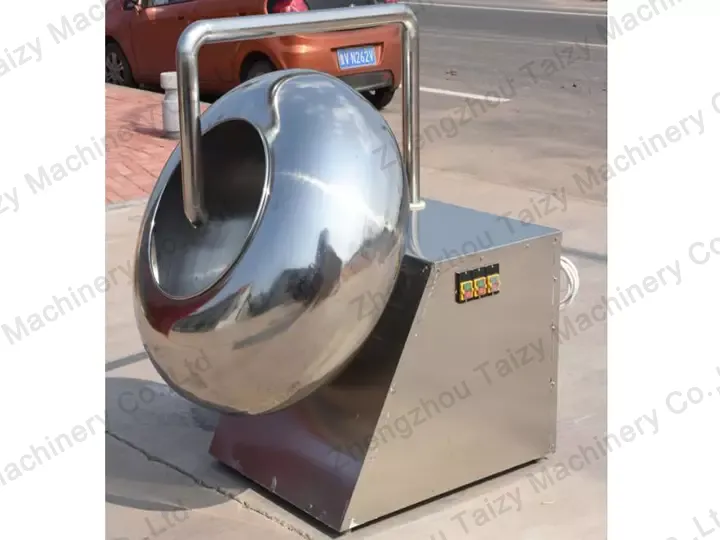

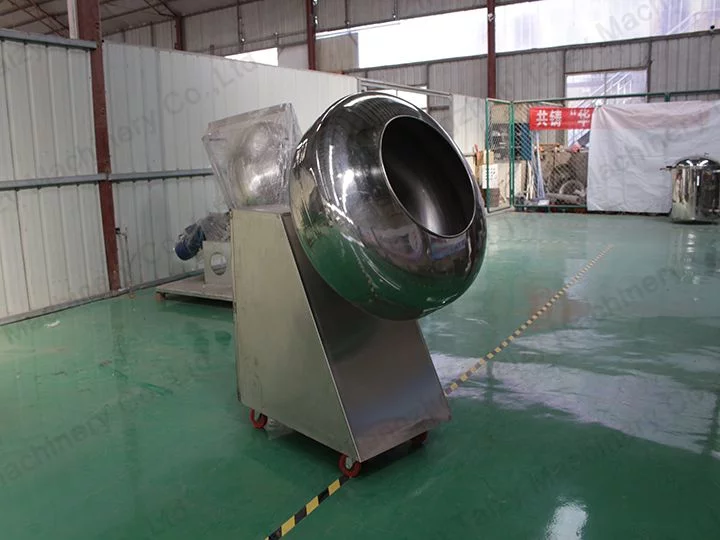

A flour coated peanut making machine is an industrial equipment used in food processing specifically designed to coat peanuts with various flavors, coatings, or seasonings. These machines come in various sizes and designs, equipped with mechanisms to evenly apply coatings to peanuts while ensuring consistency in flavor and texture.

Coated peanut machines are commonly used in the snack and confectionery industries to create coated peanuts that are popular as snacks. They facilitate the process of coating by providing a controlled environment where peanuts are rotated or tumbled while the coating, which could be chocolate, sugar, spices, or other flavorings, is applied.

Why Do Peanut Coating Machines Matter in Food Processing?

Peanut coating machines are instrumental in the food industry, offering precise and uniform coating application to peanuts. This equipment enhances the texture, flavor, and overall quality of the end product, meeting the stringent standards of today’s discerning consumers. Manufacturers rely on these machines to streamline operations, reduce manual labor, and achieve higher output rates while maintaining product consistency.

Critical Elements of High-Quality Coated Peanut Machines

When exploring coated peanut machines, several key features warrant attention. Opt for machines with adjustable speed controls, ensuring flexibility in coating application for different types of peanuts and desired textures. Additionally, look for models equipped with a user-friendly interface, easy cleaning mechanisms, and durable construction to withstand continuous production cycles.

Determining the Cost of Peanut Coating Machines

The cost of a peanut coating machine varies based on multiple factors. Considerations such as capacity, technology advancements, brand reputation, and additional functionalities influence the pricing. Generally, entry-level models might start at a lower price point, while high-capacity or specialized machines might require a larger investment.

How Do Peanut Coating Machines Elevate Production Efficiency?

Investing in a high-quality flour coated peanut making machine yields numerous benefits for food processing businesses. Enhanced efficiency, reduced manual labor, consistent product quality, and the ability to meet market demands are among the advantages. Additionally, these machines contribute to minimizing wastage and maximizing overall productivity, making them a valuable asset in the food manufacturing industry.

Making Informed Choices for Optimal Production Output

Flour coated peanut making machines are indispensable in the food processing sector, offering substantial advantages in terms of efficiency, product quality, and operational streamlining. By understanding the crucial features, pricing determinants, and benefits associated with these machines, businesses can make informed decisions, optimize their production processes, and meet consumer demands effectively.