Peanut Coating Machine for Coating Groundnut, Nuts

Peanut coating machines have become essential equipment in the food industry, allowing manufacturers to achieve evenly coated and flavorful peanut products. In this article, we will delve into the world of peanut coating machines, exploring the various types available, their potential applications beyond peanuts, and important maintenance requirements to ensure optimal performance.

What are the different types of peanut coating machines available?

Peanut coating machines come in several types, each designed to cater to specific coating needs. Here are some common variations:

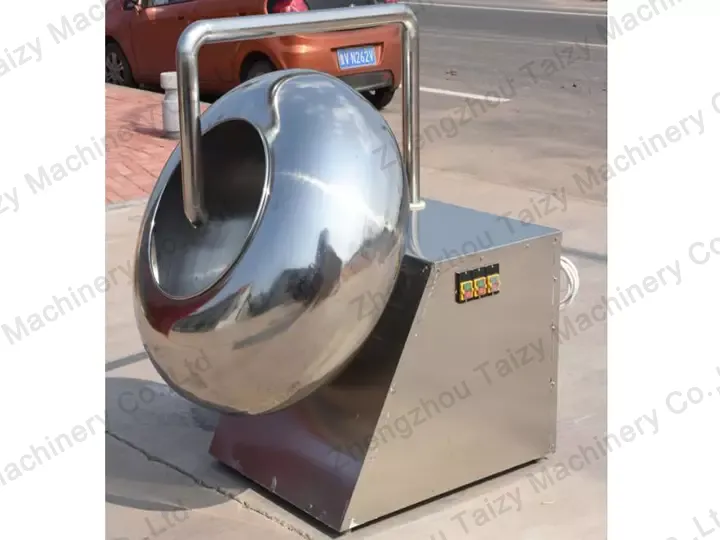

- Drum Coating Machines: These machines feature a rotating drum where the peanuts are placed. The drum is equipped with baffles and sprayers to evenly distribute the coating material, such as chocolate or flavoring agents, onto the peanuts.

- Batch Coating Machines: As the name suggests, batch coating machines process a fixed quantity of peanuts in each batch. They employ a variety of methods, including spray coating or cascading, to evenly coat the peanuts with the desired ingredients.

- Continuous Coating Machines: Designed for high-volume production, continuous coating machines employ a conveyor system to move the peanuts through a continuous coating process. They ensure a consistent and efficient coating application.

Can a peanut coating machine be used for coating other types of nuts or snacks?

Yes, peanut coating machines can be versatile tools capable of coating various types of nuts and snacks. These machines can be adjusted to accommodate different product sizes and shapes, making them suitable for coating almonds, cashews, sunflower seeds, and even snacks like potato chips or pretzels. By adapting the coating materials and adjusting the machine settings, manufacturers can achieve a wide range of delicious and coated snack options.

Are there any specific maintenance requirements for a peanut coating machine?

To ensure the longevity and optimal performance of a peanut burger coating machine, it is important to follow specific maintenance guidelines. Here are a few maintenance requirements to keep in mind:

- Regular Cleaning: Thoroughly clean the machine after each use to remove any residue or build-up. Pay special attention to the coating drum, nozzles, and spray system.

- Lubrication: Properly lubricate the machine’s moving parts, such as gears and bearings, to prevent friction and ensure smooth operation. Follow the manufacturer’s recommendations for the type and frequency of lubrication.

- Inspection and Adjustment: Regularly inspect the machine for any signs of wear or damage. Check for loose bolts, worn-out belts, or misaligned components. Make necessary adjustments or replacements promptly.

- Calibration: Calibrate the machine periodically to maintain accurate coating thickness and even distribution.

- Operator Training: Train the operators on proper machine operation, safety protocols, and maintenance procedures to minimize errors and maximize efficiency.

The price of peanut burger coating machine

Peanut coating machine prices depend on several factors, including machine type, size, brand, and features. The price of a basic model peanut coating machine usually ranges from a few thousand dollars to tens of thousands of dollars. Larger scale or high-end models of peanut coating machines may cost more.

In addition, the price of peanut coating machine is also affected by suppliers and geographical locations. Different suppliers may have different pricing strategies and promotions. In addition, factors such as market demand and currency exchange rates may also have an impact on prices

Why buy a peanut coating machine?

Peanut coating machines offer an efficient and reliable solution for achieving uniform and flavorful coatings on peanuts and other snacks. With different types available, these machines can be adapted to suit diverse coating requirements. Furthermore, by adjusting the settings and materials, manufacturers can utilize these machines for coating various nuts and snacks.